is composed of a rod or series of rods mounted

indicate FO levels in the tanks, indications of valve

vertically within the tank. The magnetic float is

alignment, alarms for high and low tank levels,

cylindrically shaped and has a hole in the center.

and, in the seawater-compensated system, an

As it moves up and down on the surface of the

alarm for receiving tank overpressurization.

fluid, the magnetic float operates tap switches

in the rod. The electrical resistance of the

TRANSFER SYSTEM.--The FO transfer

transmitter changes according to which rod

system transfers FO from the storage tanks to the

service tanks. In the transfer process, the FO is

switches are closed. This provides an indication

cleaned for use in the GTEs. The system has

of tank level. The float movement is transmitted

to a receiver that is calibrated in gallons.

transfer pumps, heaters, and centrifugal purifiers.

Magnetic-float, liquid-level indicators in tanks

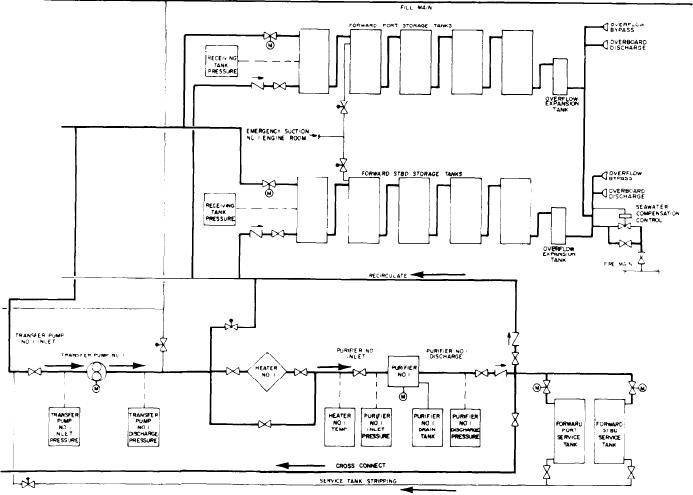

Figure 4-6 is a basic diagram of the FO

that overflow directly overboard have integral,

transfer system for the DD-class ship. It should

high-level alarms to warn of an impending over-

give you a good idea of how the system works.

board oil discharge. These alarms are set to sound

The oil king's first step is to decide from which

when the tank has reached 95 percent of total

storage bank FO is to be taken and to which

capacity. This alarm warns that the tank will

service tank it is to go. The FO is moved from

overfill and that oil will be discharged overboard

the storage tank by the transfer pump through the

FO transfer heater. The heater warms the FO to

unless the operator takes preventive action(s). On

the proper temperature for cleaning by the

most gas turbine ships, the FO system is

purifier. The FO purifier removes water and

monitored from a central point on the ship. A

contaminants as FO is transferred to the service

system control panel has gauges and alarms that

Figure 4-6.--DD-class ship fuel oil system.

4-14