their own weight into the sump. The flow through

pumps. The heaters are heat exchangers of the

the separator elements is from the outside to the

conventional shell and U-tube type. Either steam

inside. The FO, free of contaminants, then flows

or hot waste water is used with a temperature-

out of the coalescer through the discharge valve

regulating valve to maintain the FO at normal

into the FO system.

operating temperatures. An alarm in the system

When the water/sediment level in the sump

indicates high FO temperature to the plant

operator.

reaches a preset level, the automatic drain valve

dumps into the water/sediment waste oil system.

A sampling valve is provided at the discharge

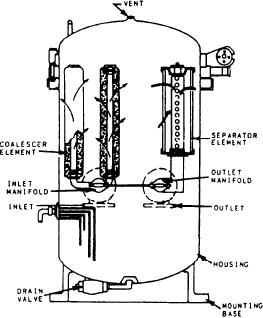

FILTER/COALESCER. --The filter/coalescer

point for testing discharged FO.

(also called the coalescer) is the last conditioning

As you can see, both the compensated and

station before the FO is used in the GTEs. The

noncompensated FO systems are basically the

coalescer filters sand, dust, dirt, and scale from

same in their operation. However, the quality of

the FO. The coalescer also coalesces water

the FO must meet stringent requirements. These

particles and removes essentially all free water

requirements help to protect the GTEs from

from the FO supplied to the propulsion gas

turbines.

serious damage, such as corrosion of the hot

section, fouling of engine controls, and plugging

The coalescer (fig. 4-8) is a self-contained,

of fuel nozzles. This level of FO quality is achieved

static, two-stage unit that combines the process

through the continuous purification, sampling,

of filtration and water separation in one housing.

and testing of FO throughout the system. This is

The basic principle of operation is that con-

the responsibility of the oil king on board the ship.

taminated FO enters the unit through the inlet

port and flows into and through the coalescing

JP-5 SYSTEM

elements. The flow through the coalescer elements

The JP-5 system provides FO to the helicopter

is from the inside to the outside. The coalescer

fueling station and to the small boat refueling

elements remove solid contaminants from the FO.

station. It also transfers JP-5 to the ship's FO

As FO passes through the elements, entrained

service system under emergency conditions to

water coalesces into large droplets that fall

operate the main engines and generators. On

to the bottom of the coalescer (sump) where they

the CG-, and DD-class ships, JP-5 can be

accumulate.

introduced into the system through the system

After passing through the coalescer elements,

piping just before it enters the FO booster pumps.

the FO passes through the hydrophobic screen and

On the FFG-class ships, JP-5 is normally provided

the separator elements, which remove the final

to emergency head tanks, which provide enough

traces of coalesced water that have not fallen by

FO for the normal cool down period (5 minutes)

of a main engine.

The JP-5 system is basically similar to the

ship's FO and transfer system in that it has

refueling stations, storage tanks, transfer pumps,

service tanks, and filter separators that provide

clean FO to the equipment. Onboard FO capacity

for JP-5 is much less than for fuel, naval distillate.

JP-5 is taken on board from topside fueling

stations and transferred to the storage tanks. The

storage tanks are noncompensated tanks and have

the same type of tank level indicators as the fuel,

naval distillate tanks. The FO is transferred from

the storage tanks to the service tanks through the

JP-5 transfer pump and filter separator. The filter

separator removes water and contaminants from

the FO before it reaches the service tanks. The

transfer piping system also branches off before

it reaches the service tanks. This provides JP-5

for emergency use in the ship's FO system and

also to the small boat refueling station.

The FO from the service tanks is used for

helicopter (helo) refueling and has its own JP-5

Figure 4-8.--Filter/coalescer assembly.

4-16