service pump and filter separator. The service

class ships, bleed air is also provided from

system provides the capability to refuel and

the 14th stage of the GTG compressor. Bleed air

recirculate FO for the helo station. Helo defueling

is used aboard ship for starting, anti-icing, masker

capability is also provided. This capability is

air, and prairie air.

necessary because FO removed from the helo is

BLEED AIR START SYSTEM

returned to the storage tanks or diverted to a

separate contaminated FO tank. A stripping pump

Bleed air used for starting is extracted from

is provided on both types of ships for removal

the compressor section of the GTE and passes

of water and sludge accumulations on the bottoms

through a regulating valve. The bleed air is

of the tanks.

regulated at 75 psi and has a maximum

As with the fuel, naval distillate, stringent

temperature of 925F. It then enters the bleed

requirements for FO purity are necessary. The

air header and is used for the various purposes

responsibility for testing the FO again belongs to

mentioned previously.

the oil king.

The CG-, and DD-class ships use

starter air differently from the FFG-class ships;

therefore, the systems differ in their method of

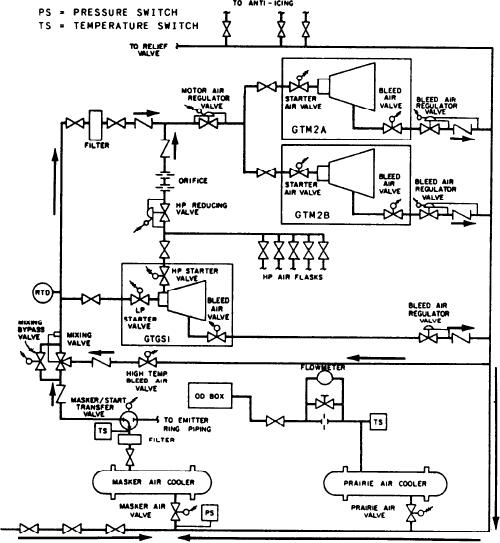

BLEED AIR SYSTEM

cooling the bleed air and directing it to the starter.

Bleed air, as we discussed in chapter 2 of this

On the CG-, and DD-class ships, bleed

TRAMAN, is compressed air taken from ports

air is the primary method of starting the GTEs

on different stages of the engines. On all classes

and SSGTGs. The bleed air of the four GTEs

of ships, the LM2500 GTE provides customer

and three GTGs enters a common header and

bleed air for shipboard use from the 16th

can be used to start any other engine or generator.

stage of the compressor. On the CG-, DD-, and

Refer to figure 4-9, a piping diagram of the

Figure 4-9.--Piping diagram of a DD bleed air system in the forward engine room.

4-17