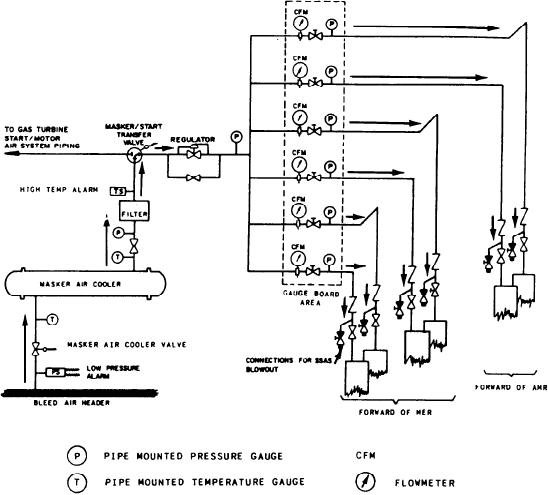

flows through the reducing valve where it is

it to 190F, and distributes it to the masker

reduced to 38 psi. It then branches out into two

emitter rings outside the ship's hull. This reduces

piping systems going to the demister pads. When

or modifies the machinery noise being transmitted

anti-icing is activated, bleed air is discharged

through the hull to the water. Refer to figure 4-11,

on the inlet side of the demister pads through

a diagram of the CG, and DD masker air

flexible piping to prevent icing on the demister

system, to help you understand the following

pads for both module cooling air and combustion

paragraphs.

air. Bleed air is also provided to the intakes for

Bleed air at 500 to 800F and at 75 psig from

module cooling and combustion air to heat the

the bleed air header enters the masker air system

inlet air after it has passed through the demister

within each engine room and is directed to the

pads.

masker air cooler valve. After the hot bleed air

has passed through the masker cooler valve, it is

MASKER AIR SYSTEM

piped to the masker air cooler where it is cooled

to 190F. The masker air cooler is a shell and tube

Because of the existing differences between the

type of cooler. It uses seawater as the cooling

ship classes, we will describe their masker air

medium. The cooled masker air is piped through

systems separately.

to the masker air filter to remove any solid

contamination and then to the masker/start

transfer valve. The masker/start transfer valve

CG, and DD Masker Air System

controls the flow of the 190F masker air to either

The CG, and DD, masker air system

the masker air system or to the gas turbine

takes hot bleed air from the bleed air system, cools

start/motor air system. Push buttons at the

Figure 4-11.--CG, and DD masker air system.

4-20