air flow. The ambient air temperature sensor

After the bleed air passes the anti-icing, air-

signal determines the magnitude of valve position

flow regulator valves, it becomes anti-icing air and

change that will accompany any given engine

is piped to the GTGS intakes. Anti-icing air

speed change. Following an engine speed change,

entry into a GTGS intake is made through an

the controller will again regulate the temperature

8-inch pipe. The hot anti-icing air flows into the

of the inlet air in the intake to 38F. It does this

intake duct and mixes with the intake air. No

by comparing the bulk air temperature to the

manifolds or nozzles are used.

controller's 38F fixed temperature reference.

Injection of hot anti-icing air into the GTE

The controller used to operate the anti-icing

intakes is accomplished through the U-shaped

valve for each GTGS intake combines and

manifolds mounted at the 02 level above the

compares one input signal (duct air temperature)

silencers inside each duct. The manifolds are

with the fixed temperature signals (38F) to

constructed from 8-inch diameter pipe with

produce a torque motor control position signal.

1 1/4-inch holes drilled along the sides of each

The anti-icing valve used on a GTGS is the same

leg. Because of the larger cross-sectional area and

as that used on a GTM.

capacity of the propulsion intakes, manifolds

When the GTGS anti-icing temperature

must be used to mix the air thoroughly.

controller is enabled, it maintains the temperature

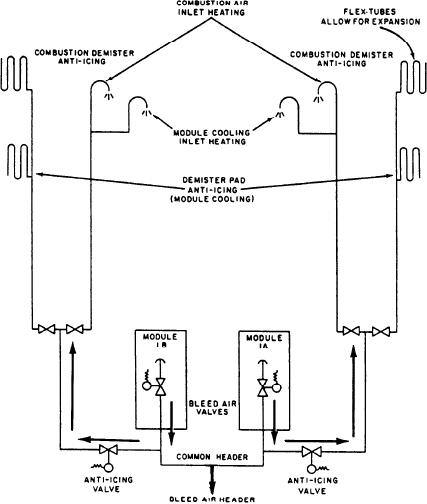

FFG Anti-Icing System

of the inlet air in the intake at 38F. Again the

controller compares duct air temperature to the

In the FFG anti-icing air system (fig. 4-10),

38F fixed temperature.

bleed air is taken from the common header and

Figure 4-10.--FFG anti-icing system.

4-19