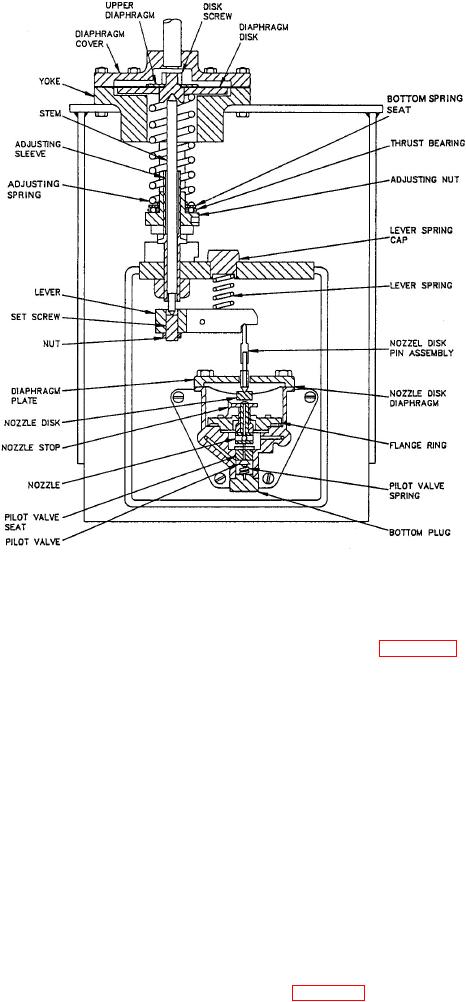

Figure 4-4.-External control pilot.

hole and stem collar seal for air leakage, and check

external air source with an in-line pressure regulator

the externally mounted pilot controllers, such as the

that is connected to the diaphragm inlet air

one shown in figure 4-4, for proper supply air

connection. With the air pressure regulator set at

pressure settings.

zero psi, the valve position indicator should be

pointing at zero percent on the position scale,

TEMPERATURE CONTROL VALVES. The

indicating a normally closed valve. As you apply air

pressure to the diaphragm, the valve should begin to

types of temperature control valves we normally use

open. The amount of air pressure you apply to the

are either the air pilot operated valves, such as the

valve will determine the percent of valve opening,

one we described earlier, or the spring-loaded,

depending on the valve spring pressure. Normally, all

bellows-actuated valves. These two valves are used in

of these valves will require approximately 5 psi of air

almost every system in the engineering plant. You

pressure to start valve stem movement. At 20 to 22

will find either one located near every heat exchanger

psi, the valve should be fully open. If more air

in the plant.

pressure than 22 psi is required to move the valve

stem, there is a good possibility the diaphragm has a

Pilot Operated Valves. The tests and

hole in it, the stem seal is leaking, or the valve is

inspections you will use for the pilot operated valves

binding. Any one of these problems can seriously

are the same as those we previously described for the

affect the responsiveness of the valve, so you should

level control valves.

investigate these conditions as soon as possible.

Spring-Loaded Bellows Actuated Valves. A

Generally, you will perform an inspection of a pilot

typical spring-loaded bellows actuated valve is shown

operated valve during normal valve operation.

in figure 4-5. For this valve, you will normally

During the inspection, you will need to check the

conduct

packing gland for leakage, watch the stem cycle for

smooth operation, examine the diaphragm telltale