to override a pneumatic or electrical type of actuator

in the case of an actuator or control valve failure. For

example, the steam diverting valve used on the CG-

47 and DD-963 class ships has a valve handwheel.

The handwheel is coupled directly through the

diaphragm to the valve stem to allow for manual

operation of the valve.

MECHANICAL LINKAGES. The purpose of

valve operator mechanical linkages is to connect

remotely positioned valves with an operator

handwheel by a series of rods (linkages) or a flexible

cable. Valve operator mechanical linkages are needed

to control hard-to-inch valves, such as those located

in the bilge area or the overhead. With proper

maintenance and upkeep, these mechanical operators

serve as real time savers.

Now that we have discussed some of the automatic

control valves in terms of their basic operations and

components, let's talk about how you will be required

to test, inspect, and maintain them.

Tests and Inspections

In this section, we will briefly discuss some of the

tests and inspections you may be required to perform

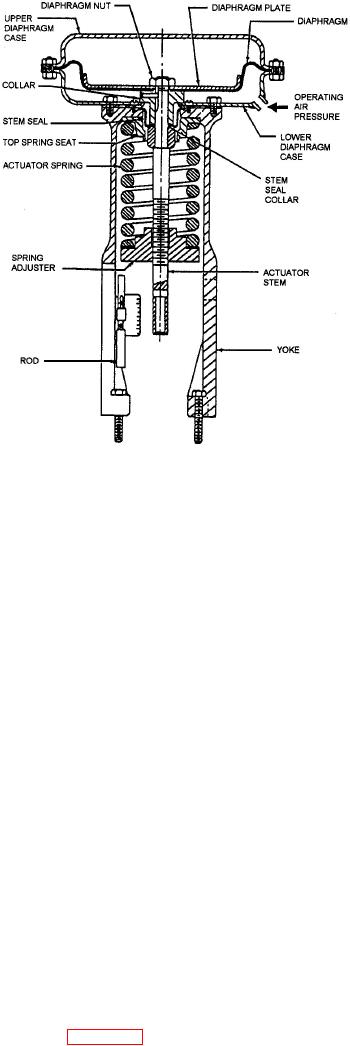

Figure 4-3.-Diaphragm control valve actuator.

on the various types of control valves and other

associated components. Normally, you will conduct

Solenoid Valves. Solenoid valves are used

periodic tests and inspections when the component is

extensively throughout the engineering plant of any

operating or according to approved maintenance

gas turbine-powered ship. The solenoid valve we will

procedures, such as the PMS.

discuss as our typical example is the one that is used

as a level control device in the FO service system on

LEVEL CONTROL VALVES In testing and

DD-963 class ships. These valves do not have any

inspecting level control valves, you will sometimes

specific tests or inspections as per PMS. According to

require the assistance of a GSE. If the test or

the NSTM, Chapter 505, "Piping Systems," however,

inspection pertains only to the valve itself or if the

extensive damage may occur if these valves are not

sensing features of the system are mechanical, such

exercised periodically. This is particularly true if the

as those on the WHBs, then you will be able to

valves are located in areas that are difficult to keep

complete the checks on your own. If the operation of

clean, such as the bilges in main engine room (MER)

the tank level sensing system you must test or

No. 1.

inspect is electrical, however, then you will need the

assistance of a GSE.

Solenoid valves should always be cycled before the

system is placed in operation. For proper operation,

Frequently, you will inspect the operation of a

they should also be cycled at least once per month.

level control valve during normal operation. You will

You can perform an operational test on a solenoid

normally perform tests on this valve during a

valve by using the thumbwheel override built into the

training evolution or a propulsion plant inspection, or

side of the valve. When performing a test or

when you are planning to perform general

inspection, you should be checking for proper

maintenance. Regardless of the circumstances, you

operation of the valve and leaks around the stem or

must perform your inspections and tests of these

associated fittings and flanges.

valves according to the PMS or other authorized

procedures just as you would for any other test or

Pilot Operated Valves. Pilot operated valves

inspection you are required to accomplish.

are normally tested and inspected according to the

PMS. In performing a normal test, you will check the

Basically, the two most popular types of level

full travel range of the valve stem and match it with

control valves you will need to be familiar with are

the scale mounted on the control valve actuator yoke,

the solenoid-operated, needle type and the

as shown in figure 4-3. To perform this test, you must

pneumatic-operated globe type.

use an