5. You should enter the cartridge time delay,

part number, type, expiration date, lot number,

can open/installation date, the CAD DODIC (De-

partment of Defense Identification Code), and the

date of manufacture or overhaul on the parachute

Configuration, Inspection, and History Record.

6. Insert a proper time-delay cartridge in the

barrel. Refer to the applicable parachute chapter

to determine which time-delay cartridge should

be used. While you are pressing down on the

barrel, look through the inspection hole in the

receiver and ensure that the hammer assembly

does not swing towards the firewall. If the

hammer swings, the arming pin is improperly

installed. Do not attempt to assemble the ripcord

release any further, as this could fire the cartridge.

7. Press the barrel down into position in the

receiver (fig. 2-10). As the barrel reaches proper

position, exert forward pressure on the snap lock.

This causes the snap lock pins to lock the barrel

in position. Ensure that the snap lock is aligned

with the alignment arrow.

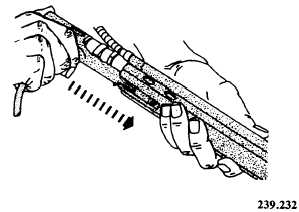

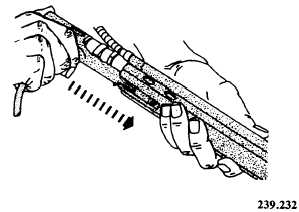

8. Hold the ripcord release, as shown in figure

2-13, and slide the receiver and barrel assembly

into the cover and power cable assembly until the

holes for the screw are aligned.

9. Install the locking screw and lock washer.

Apply a tamper dot to the locking screw, using

red lacquer.

CHECKOUT OF ARMED RIPCORD

RELEASE

To check out an armed automatic ripcord

release, you should proceed as follows:

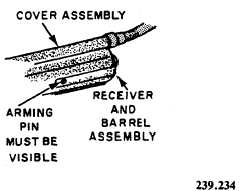

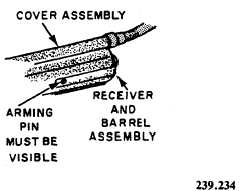

1. Check the arming cable for proper

installation, as shown in figure 2-14. The arming

pin must be visible (extending through the side

of the receiver).

Figure 2-13.—Sliding receiver and barrel into cover assembly.

Figure 2-14.—Checking arming pin for proper installation.

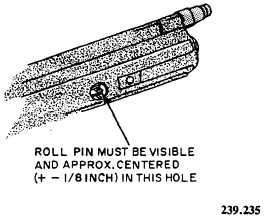

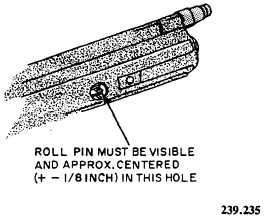

Figure 2-15.—Checking roll pin.

2-15).

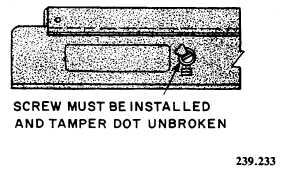

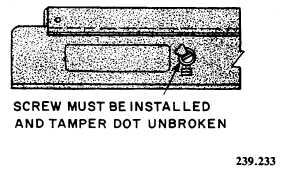

Figure 2-16.—Checking lock screw.

2. Check for correct position of the

spring and centering of roll pin in hole (fig.

3. Check to make sure the locking screw is

installed. Be sure that the tamper dot isn’t broken

(fig. 2-16).

2-8