inspections.

You will find more detailed

information concerning automatic parachute

ripcord release assemblies in the Emergency

Personnel and Drogue Parachute Systems

Manual, NAVAIR 13-1-6.2, and the Maintenance

Requirements Cards, NAVAIR 13-600-4-6-3.

MAINTENANCE

Maintenance on any automatic ripcord release

in service must be performed each time its

parachute assembly is repacked. Maintenance

consists of the following:

. Disarming

. Inspection

. Firing altitude check

. Arming and assembly

. Checkout of armed mechanism

As you work on a automatic ripcord

release assembly, you are required to per-

form several different types of maintenance

and inspections.

You are required to in-

spect the operational condition of the auto-

matic ripcord release before installing it in

a parachute assembly. If you find any damage

or an inspection discrepancy, submit a quality

deficiency report, as discussed in OPNAVINST

4790.2 (series).

NOTE: Under no circumstances should

an unsatisfactory ripcord release be in-

stalled.

The first step in performing the normal

inspection and maintenance on a automatic

ripcord release is to disarm it. Then you are ready

to inspect and perform the firing altitude checks.

DISARMING

Anytime you are required to disarm a ripcord

release assembly, follow the procedures outlined

in NAVAIR-13-1-6.2. The discussion that follows

closely parallels those procedures. A parts

breakdown can be seen in figure 2-1.

NOTE: To remove the arming cable

housing from the ripcord release, de-

press the safety retainer release (fig. 2-1).

NEVER try to remove the arming cable

from an armed ripcord release assembly by

pulling on the cable. This fires the auto-

matic ripcord release.

1. Open the ripcord release pocket, and

remove the ripcord release only a sufficient

distance to allow disassembly.

2. Remove the locking screw and washer.

NOTE: The cover and power cable

housing assembly and the receiver and

barrel assembly are serialized matched sets.

Do not mix these assemblies.

3. Slide the cover off the receiver and barrel

assembly.

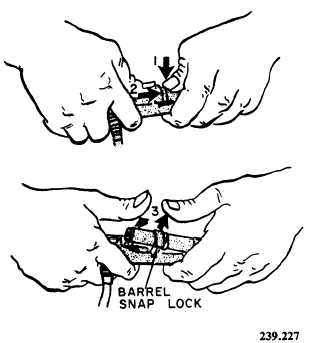

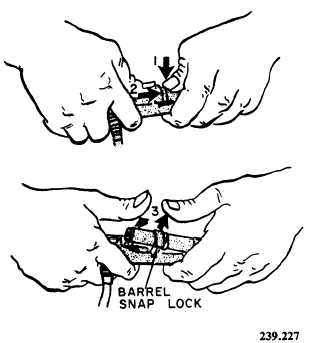

4. Disengage the barrel snap lock. A close-up

of this operation is shown in figure 2-2.

5. Remove the cartridge from the barrel as-

sembly (fig. 2-1). Do not proceed until the quality

assurance inspector (QA) has verified this step.

6. Remove the ripcord release assembly and

the arming cable housing from the parachute

container.

Figure 2-2.—Disengaging barrel snap lock.

2-3