18. Clean the cartridge chamber and threads

with a small amount of denatured alcohol. Ensure

that the old sealing compound and all foreign

matter is removed. Tilt the gun to allow the

alcohol to run out of the gun.

19. Feel the inside of the cartridge chamber

to ensure that the slug pistons do not stick out

inside the chamber. If the pistons do protrude,

push them back as necessary. Feel the bottom of

the chamber to ensure there is no foreign object

in the chamber. The bottom should be smooth

metal.

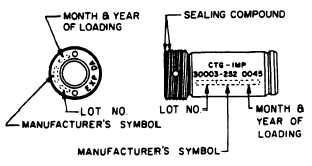

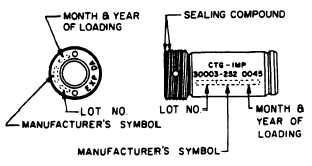

20. Prior to the cartridge installation, stamp

on the cartridge, in the approximate position

shown in figure 2-26, the following information:

lot number, manufacturer’s symbol, month and

year of loading. Use black marking ink and make

the characters as large as practicable for the

available space. The same markings, plus ex-

piration date and the can open date, must also

be stamped on the cartridge head, using characters

no smaller than 1/16 inch high.

21. Record the type of cartridge, part number,

delay time, lot number, and service life expiration

date on the Parachute Configuration, Inspection,

and History Record.

22. Apply sealing compound to the top two

threads of the cartridge. (See figure 2-26.)

Figure 2-26.-Cartridge markings-head and side.

23. Attach the new cartridge to the retaining

cord by passing the pin through the screw base

of the cartridge and the loop that is located at the

end of the retaining cord.

NOTE: Never force the cartridge into the

chamber. This could damage the gun.

When a cartridge is properly installed, the

base should be approximately even with

the top edge of the chamber. If the

cartridge base is more than one thread

above the edge, remove the cartridge and

check the bottom of the chamber for any

obstruction,

such as protruding slug

pistons.

24. Having inserted the cartridge into the

chamber, you tighten it manually. If the cartridge

stops before the threads are engaged, remove the

cartridge and again check for protruding slug

pistons. Push them back if necessary.

25. Replace the gun in the clamp or V-block

assembly in accordance with steps 3 and 4. Using

a cartridge extractor wrench and torque wrench

with a 3/4-inch socket, you must torque the

cartridge to 84 inch-pounds (plus or minus 12

inch-pounds).

26. Remove the spreading gun from the clamp

or V-block assembly. Do not remove the safety

pin. Put the cartridge extractor wrench back on

the swivel/stanchion bolt.

27. Check stowage of the firing lanyard.

Restow it if necessary.

28. Close the extractor sleeve. Now your job

has been completed.

To install a ballistic spreader gun onto a

parachute, you must refer to the Emergency

Personnel and Drogue Parachute Systems

Manual, NAVAIR 13-1-6.2. Repacking a

parachute with a ballistic spreader gun is discussed

in chapter 3 of this manual.

2-15