torso harness suit as part of an ejection seat escape

system.

The NES-12 parachute assemblies include a

modified 28-foot diameter, flat nylon canopy with

28 gores. A ballistic spreading gun is used to

rapidly deploy the canopy. The canopy is packed

in a semirigid contoured container. These

assemblies also include the tristage external pilot

chute (EPC) and an internal pilot chute. The riser

assembly, which includes the shoulder restraint

system, is rigged to the container and is connected

to the torso harness suit with quick-release fittings.

The integrated torso harness suit combines the

aircrewman’s parachute harness and lap and

shoulder restraint straps. The harness is channeled

through the torso suit to retain it in position and

to aid in donning. When aboard the aircraft and

seated, the aircrewman connects the quick-release

fittings on the parachute riser assembly to the

quick-release fittings on the parachute integrated

torso suit. The survival kit and the lap restraint

system are also connected to the integrated torso

suit by means of quick-release fittings.

RIGGING

To obtain the NES-12 parachute, you order

each component separately. You must rig the

parts together to forma complete assembly. When

you start to work on this or any parachute, the

rigging and packing will be done under ideal

conditions in a parachute loft. When a parachute

assembly must be packed under unfavorable

conditions, provisions must be made to protect

it from possible damage and excessive humidity.

Quality assurance (QA) points are included in

rigging and packing procedures. When a step is

followed by “(QA),” it is a QA requirement. All

work STOPS until a quality assurance inspector

performs the requirements listed at the end of the

applicable procedure.

The packing of a parachute assembly must

NOT be interrupted after the packing operation

has been started. If unforeseen circumstances

cause the packing operation to be interrupted, the

parachute assembly must be completely repacked.

The rigging covered in this chapter applies to

an original issue parachute assembly.

NOTE: This rate training manual is not to

be used as a substitute for the NAVAIR

13-1-6.2 or the NAVAIR 13-600-4-6-3

manuals.

PRELIMINARY PROCEDURES

After you have laid out the parachute and

connected the connector links to the proper

tension hooks, attach the internal pilot parachute.

This is done by routing the small loop of the bridle

assembly through the loop in the pilot parachute.

Pass the free end (large loop) of the bridle

assembly through the small loop, forming a lark’s

head knot. Draw it tight. Pass one free end (large

loop) of the bridle assembly around the canopy

vent lines at the peak of the canopy. Pass the pilot

parachute through the large loop of the bridle

assembly, forming a lark’s head knot, and draw

tight. Now, attach a tension strap to the canopy

vent lines and tighten it.

At this time, you should inspect the complete

parachute assembly following the directions in

NAVAIR 13-1-6.2 and NAVAIR 13-600-4-6-3.

This inspection has been covered in chapter 1 of

this manual.

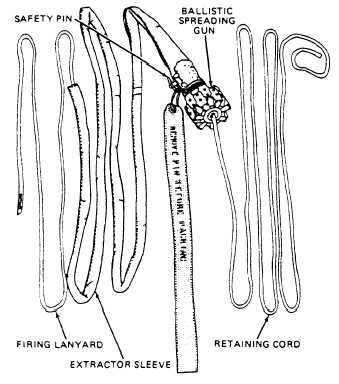

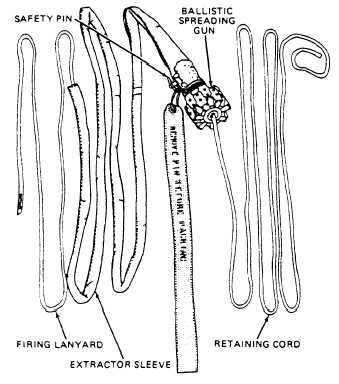

INSTALLATION OF SPREADING GUN

A ballistic spreading gun (fig. 3-3) is used

in the parachute. The procedures for inspect-

ing this device was discussed in chapter 2.

After the parachute has been inspected and

Figure 3-3.—Ballistic spreading gun assembly.

3-4