the smaller the number, the smaller the size of the

grommet.

To install grommets, you must proceed

through a series of operations. Locate and

mark where a grommet installation is needed.

Be sure you set the grommet far enough from

the edge of material to prevent it from tearing.

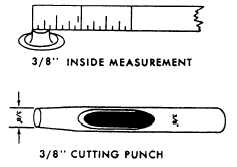

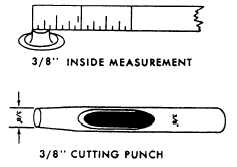

Select the correct punch by matching its size to

the size of the grommet collar, as shown in figure

10-11.

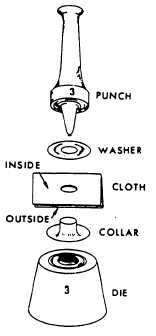

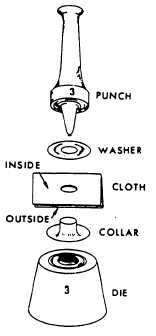

After you have used the leather cutting

punch to cut a hole in the fabric, you

must mate the parts of the grommet. Place

the grommet on the finished side of the

material and the washer underneath. Deter-

mine the correct size chuck and die. As-

semble the grommet, washer, punch, and

die, as illustrated in figure 10-12. Now you

are ready to flatten the collar. This opera-

tion can be accomplished in a variety of

ways,

depending upon the availability of

tools .

Grommet Press Installation

You may have a foot-operated grommet press

or a hand press, as illustrated in figures 10-6 and

10-7. To use either type of press, you need an

assortment of chucks and dies. Install the die in

the bottom of the press and the chuck in the top

of the press. Set the foot press and check for a

clearance of the thickness of heavy paper between

the chuck and die. This prevents damage by

striking the chuck and die together. By depressing

the foot pedal or handle, you securely flatten the

grommet.

239.374

Figure 10.11.—Inside diameter measurements.

239.375

Figure 10-12.—Grommet collar, cloth, and washer in

grommet set.

Grommet Set Installation

A grommet set, consisting of a punch and

die, is used to install grommets in material.

Figure 10-12 illustrates a grommet set. The

grommet set has to be the same size as

the grommet for a proper grommet installation.

Use a rawhide mallet to strike the punch. This

action flattens the grommet. The grommet set

installation is used because of its simplicity and

portability.

GLOVE FASTENERS

The most common type of fastener used on

clothing and other items made of fabric and

rubber is the glove fastener. In many instances,

the glove fastener has replaced the conventional

button. Glove fasteners are dependable and are

used for their holding and firm gripping ability.

Figure 10-13 shows the three different types of

glove fasteners most commonly used. The main

difference between the three fasteners is size. The

Segma Dot is the smallest; the Durable Dot is the

largest type of glove fastener. Each fastener is

made of four parts: button, socket, stud, and

10-13