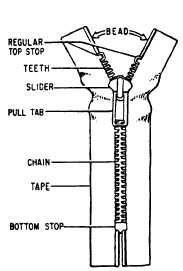

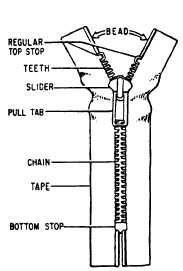

Figure 10-18.—Slide fasteners.

figure 10-18. Figure 10-19 shows the parts of an

the slider, which, when moved, displaces teeth at

interlocking fastener.

Interlocking Slide Fastener

Construction

An interlocking slide fastener consists of two

chains of teeth (hollow cones or scoops) facing

each other. When brought together at the proper

angle, each tooth fits within the scoop of the tooth

opposite it.

When closed, the interlocking slide fastener

teeth cannot be parted except through the use of

the proper angle for meshing and unmeshing. The

small clips (stops) at the top and bottom of the

interlocking slide fastener are designed to prevent

the slider from running off the track. Separating-

type slide fasteners do not have a bottom stop,

but are equipped with a pin on one side and

retainer arrangement on the other to allow the two

parts of the slide fastener to separate.

Interlocking Slide

Fastener Operation

Ordinary interlocking slide fasteners are

designed for flat, smooth operation. Both hands

are required for proper functioning. The chains

should be stretched taut with one hand and the

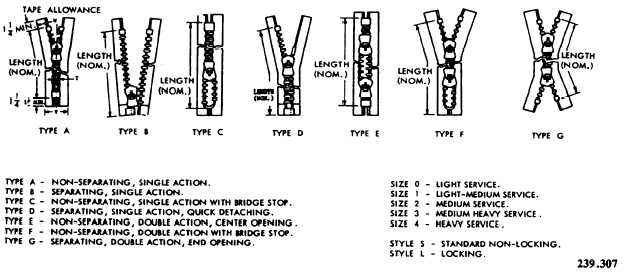

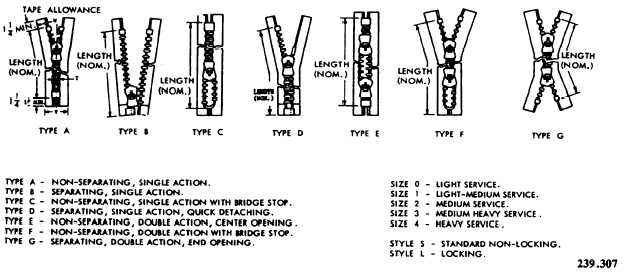

Figure 10-19.—Slide fastener

239.308

parts.

10-16

slider worked (without force) with the other.

When operating an interlocking slide fastener

installed in a garment of soft nappy material, or

lined with wool or fur, do so with care to prevent

the nap or wool from jamming the slider.

Very often grease or oil deposits lodge between

the tiny hollow parts of the teeth and accumulate

dirt and lint. This causes stiff operation of the

slider. A dirty or gummed chain should be cleaned

with an old toothbrush or a pipe cleaner saturated

with Stoddard solvent or other similarly approved

cleaning solvent. After each cleaning, the chain

should be lubricated by applying one drop of oil

or a small amount of graphite between your

thumb and forefinger and running the chain up

and down between your fingers several times.