239.310

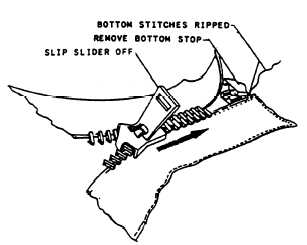

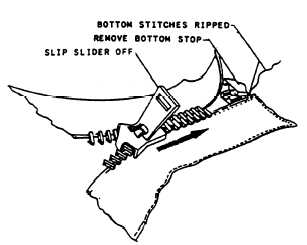

Figure 10-21.—Removing the slider.

replacing pull tabs, this procedure is reversed. Pull

tabs furnished as replacements need only to be

squeezed onto the slider.

To repair a damaged slider, you must first

remove it. The proper procedure for removing and

replacing a slider on the chain following repairs

is explained in the following paragraphs.

To remove the slider from the regular type

interlocking slide fastener (nonseparating),

carefully rip the stitches from the BOTTOM of

the interlocking slide fastener to expose the ends

of the tape. Then remove the bottom stop, and

slip the slider off the bottom of the chain and

entirely off the beads and tape, as shown in figure

10-21.

To replace the slider on a regular type

interlocking slide fastener, thread the two bottom

beads into the wide end of the slider. Hold the

tape so that the bottom teeth are correctly

matched; then draw the slider upward until the

teeth mesh for several inches. Without allowing

the teeth to separate, clamp the bottom stop close

to the teeth and over both beads. Replace the tape

ends and ripped stitches by hand or by machine.

To remove a damaged slider on a separating

type slide fastener, carefully rip the stitches at the

TOP of the slide fastener, on the retainer side

only, thus exposing the end of the tape. Remove

the top stop, slip the slider off the top of the chain,

and completely remove it from the bead and tape.

Repair or replace the slider.

To replace the slider on a separating type

interlocking slide fastener, thread the bead on the

retainer side into the narrow end of the slider, and

allow the slider to slip down the chain. Replace

the tape end and ripped stitches by hand or

machine.

To replace the slider on the top of a regular,

nonseparating type interlocking slide fastener with

the aid of pull-up pliers, slip the tool over the

bottom stop, clamp together, and pull upward.

Close the entire chain in this manner. Thread the

two top beads into the narrow end of the slider,

holding the teeth meshed until they enter the

slider. Replace the top stops, tape ends, and

ripped stitches.

Shortening an Interlocking Slide Fastener

To shorten an interlocking slide fastener, first

determine the length required. The chain should

be about one-half inch shorter than the opening

in the material or garment. Mark the desired

length, measuring from the bottom stop upward.

Open the chain to any point below this mark and

cut directly across the tape about 1 inch above

the mark. Cut the excess teeth from the marking

point to the end of the tape, and replace the two

stops, crimping them firmly.

Installing an Interlocking Slide Fastener

The installation of an interlocking slide

fastener varies with the type of job. Some are

curved, some have rounded comers, and some are

hidden. The installation of a straight slide fastener

is described in the following paragraphs.

Slide Fastener Presser Foot

To install a slide fastener neatly and easily,

you should use a slide fastener presser foot on the

sewing machine. The slide fastener presser foot

serves not only as a guide for a neat row of

stitches, but also prevents the foot from riding

up on the chain.

The sewing machine manufacturer can supply

a regular slide fastener presser foot (right or left)

for any sewing machine, or one can be made

locally. File or grind the left side of an old presser

foot to permit sewing to within 1/8 inch of the

chain.

Fabrication

When sewing, always stretch the slide fastener

and not the material, as this makes a flatter and

neater job.

10-18