Table 6-7.—Life Preserver Test Pressures

FLOTATION CHAMBER

LEAKAGE TEST

MINIMUM

PRESERVER TYPE

TEST SEQUENCE

PRESSURE (PSIG)

PRESSURE (PSIG)

LPA-2 series

Both Chambers Simultaneously

2.0

1.6

LPU-21/P series

Both Chambers Simultaneously

2.0

1.6

LPU-23/P series

Both Chambers Simultaneously

2.0

1.6

LPU-24/P series

Both Chambers Simultaneously

2.0

1.6

LPU-28/P

Single Chamber Preserver

2.0

1.6

LPU-30/P

Single Chamber Preserver

1.0

0.8

LPP, Pouch Type

Single Chamber Preserver

2.0

1.6

hose mouthpiece. Maintain pressure between the

valve on the oral inflation hose and alternately

rubber hose and the oral inflation hose

mouthpiece to ensure a good seal. Depress the

position the leakage test fixture valve between the

measuring device, vent, and air supply until the

overpressure relief valve opens (2.5 psig ± .5

psig). Rotate the leakage test fixture valve to the

measuring device position to ensure that the life

preserver is inflated to the proper pressure.

Release the valve on the oral inflation hose.

Inspect for proper operation of the relief valve.

3. To test all preserver chambers, except

LPU-28/P, unlock the oral inflation valve and

insert it into the rubber hose. Rotate the valve to

the air supply position and inflate the chamber.

Alternately position the valve between the

measuring device, vent, and the air supply until

the proper pressure is attained.

4. Turn off the air supply, and after a

minimum of 15 minutes, readjust the pressure,

if necessary, to the original pressure. Refer to

table 6-7.

5. Disconnect the air supply and check test

fixture for leaks. Ensure all valves are closed.

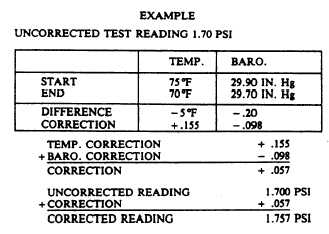

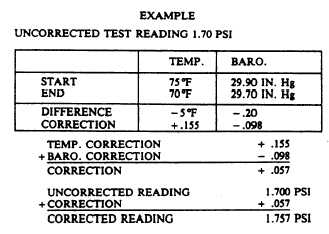

6. Record temperature and barometric

pressure.

7. Four hours after the adjustment period in

step 4, record the test pressure.

8. Record temperature and barometric

pressure and correct test pressure for any changes

in temperature and barometric pressure. Figure

6-18 is an example of how you would record this

information.

Figure 6-18.—Example for recording readings.

CAUTION

DO NOT SUBMERGE LPU-23/P

SERIES AND LPU-24/P SERIES LIFE

PRESERVERS IN WATER TO CHECK

FOR LEAKS.

After 4 hours, if the pressure of the chamber

is below 1.60 psig, inflate to leakage test pressure

and coat with a soap solution to locate any leaks.

Mark any leak area you find. Rinse the preserver

with fresh water, air dry it, and repair it in

accordance with NAVAIR 13-1-6.1.

If the preserver has held the required pressure,

deflate it. Ensure that the inflation valve lever is

cocked. Install a carbon dioxide cylinder.

6-31