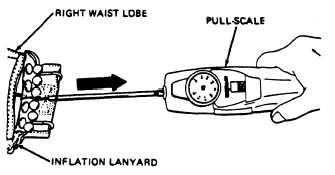

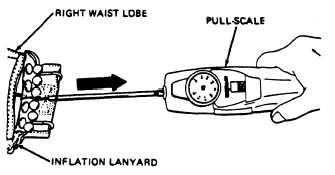

Figure 6-22.—Inflation lanyard pull test.

To perform the inflation lanyard pull test,

proceed as follows:

1. Ensure that the carbon dioxide cylinders

have been removed. Actuate the inflation assem-

bly. This test is testing the lanyard itself. It isn’t

designed to test the pull of the inflation assembly.

2. On life preservers with beaded inflation

handles, attach a pull scale to top end (end

opposite inflation lanyard) of beaded inflation

handle (fig. 6-22).

3. On LPP and LPA-1/1A life preservers,

attach the pull scale to the actuating lanyard at

the binder knot immediately above the knob.

4. Exert a 25-pound straight pull on the

inflation lanyard. Remove scale.

5. Examine the inflation lanyard for frays,

ruptures, thin spots, split casing, and security of

knots.

6. Replace any unsatisfactory inflation lan-

yards.

Installation of Cylinders: LPA-1/1A

(Series), LPA-2 (Series), LPU-21/P (Series),

LPU-30/P, and LPP-1 (Series)

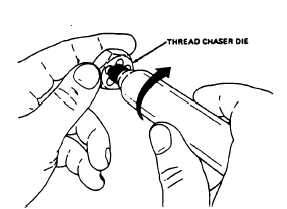

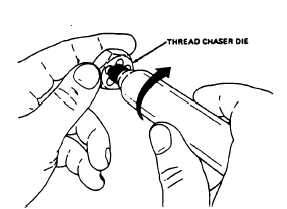

Prior to installing any CO2 cylinder, it must

be weighed and the threads cleaned. By using the

cylinder thread chaser die, you turn the thread

chaser to the full extent of the threads on the CO2

cylinder to cut free any excessive cadmium plating

covering the threads (fig. 6-23).

Weigh the charged cylinder and compare the

stamped minimum weight with the scale weight.

Discard and replace the cylinder if the scale weight

is 2 grams less than stamped minimum weight.

Loosen the inflator setscrew if it is installed and

ensure that the inflator lever is in the cocked

position. To assure a firm cylinder seat, conduct

a cylinder thread count. The threaded portion of

the cylinder neck must contain a minimum of

seven full threads to assure a firm cylinder seat

Figure 6-23.—Cleaning threads.

within the valve body. Any cylinder found with

less than seven full threads must be discarded.

CAUTION

STEEL THREADS ON CARBON DIOX-

IDE CYLINDERS CAN CAUSE DAM-

AGE TO ALUMINUM THREADS ON

INFLATORS IF THE CYLINDER IS

NOT CAREFULLY THREADED. IF

BINDING OCCURS DURING THREAD—

ING, REPLACE THE CYLINDER.

After performing a functional test, insert a

new seat seal gasket from a kit. At intermediate

inspection intervals, inspect the condition of the

gasket and replace it if necessary. Install the CO2

cylinder into the inflator as far as hand twisting

will permit. Tighten the setscrews, if installed.

NOTE: When you replace the CO2

cylinder to the inflator, ensure that the

CO2 cylinder passes through the holding

patch loop. Do not install the setscrews in

LPA-2 and LPU-21/P life preservers. For

all other life preservers, a missing setscrew

does not warrant removal of the preserver

from service until a replacement setscrew

can be obtained. Safety-wire the inflator

as required.

Installation of Cylinders, LPU-23/P

(Series) and LPU-24/P (Series)

To install cylinders, proceed as follows:

Weigh a charged CO2 cylinder and com-

pare the stamped minimum weight with the scale

6-34