CATAPULT CONTROL SYSTEMS

LEARNING OBJECTIVES: Describe the

components of the catapult control systems.

Describe the function of the catapult control

systems.

The control system of a steam catapult consists of

those panels, lights, and switches that are used to

operate a catapult throughout the various operational

phases.

ELECTRICAL CONTROL SYSTEM

COMPONENTS

The electrical control system for a steam catapult

consists of various control panels that govern the

operation of the catapult in conjunction with control

components of other systems.

Included among the components of the catapult

electrical control system are various push buttons,

switches, solenoids, relays, circuit breakers, fuses, and

lights. The ICCS, CCP, and the main control console is

the focal point of all functions of the catapult electrical

control systems.

Electrically operated solenoid valves produce

mechanical operation of valves throughout the catapult.

Buttons actuate some solenoid valves, while others

function automatically during catapult operation.

Various changes that occur during catapult operation

are sensed by limit switches and pressure switches.

Operation of these switches actuates lights at various

control panels. The following paragraphs briefly

describe some of these components. For information on

the function and interrelationship of the electrical

components in a specific system, study the schematic

diagrams in the technical manual for that particular

type of catapult.

Solenoids

A solenoid (fig. 4-51) is an electromagnet formed

by a conductor wound in a series of loops in the shape

of a helix (spiral). Inserted within this spiral or coil are a

soft-iron core and a movable plunger. The soft-iron

core is pinned or held in position and therefore is not

movable. This movable plunger (also soft iron) is held

away from the core by a spring in the de-energized

position.

When current flows through the conductor, a

magnetic field is produced. This field acts in every

respect like a permanent magnet having both a north

and south pole.

As shown in figure 4-51, the de-energized position

of the plunger is partially out of the coil, because of the

4-42

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

3

4

5

6

9

10

1

2

3

4

5

6

7

8

9

10

11

12

DECK LINE

DECK LINE

DECK LINE

DECK LINE

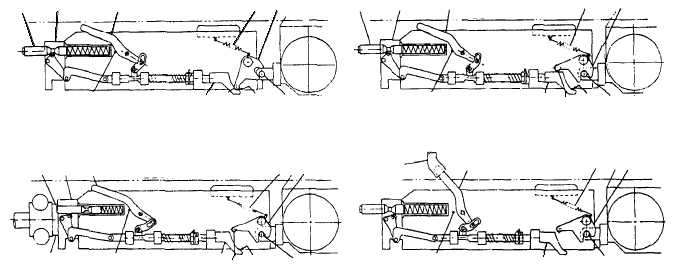

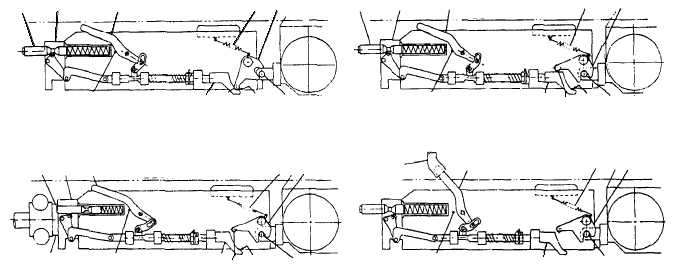

DIAGRAM A

DIAGRAM B

DIAGRAM C

DIAGRAM D

UNLOCKED POSITION - APPROACHING SHUTTLE

LATCHED & LOCKED TO SHUTTLE

UNLOCKED - SHUTTLE FREE TO MOVE FORWARD

MANUALLY UNLOCKED

ABEf0451

1. Pushrod

2. Block

3. Manual-release arm

4. Latch spring

5. Grab latch

6. Shuttle clevis pin

7. Cam detent

8. Cam follower

9. Lock block

10. Manual-release-arm stop

11. Bridle-tensioner buffer cap

12. Manual-release disengaging lever

Figure 4-50.—Grab operation sequence.