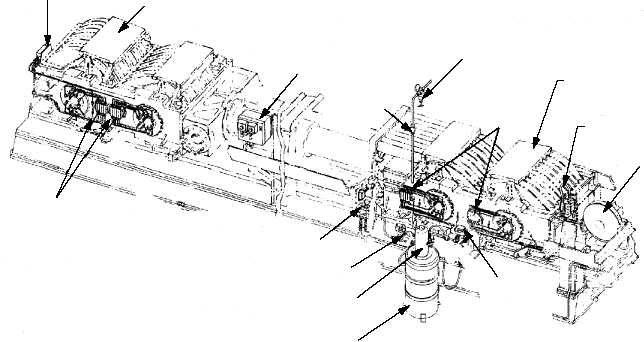

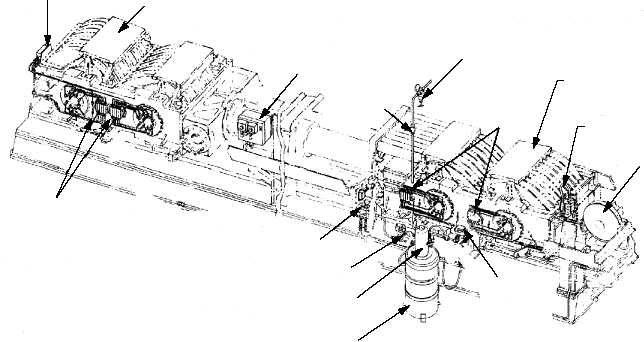

An automatic lubrication system (fig. 3-18) ensures

that lubricant is automatically provided to the arresting

engine crosshead and fixed sheave assembly during

arrestment operations (pendant engines only). The

ship's low-pressure air, is piped to a regulator, which

reduces the air to the required operating pressure of

between 75 and 85 psi. Air is fed through a rubber hose

to a pump mounted on top of a 120-pound drum of

lubricant. Lubricant is pumped from the drum through

hoses to control valves mounted on the engine

structure. These control valves adjust the rate of flow of

lubricant to the high-speed sheaves.

The control valves are operated by plunger rollers,

which are cam-actuated at a set position of the engine

crosshead arrestment stroke. An ounce of lubricant is

pumped

to

the

high-speed

sheaves

during

the

arrestment and the retraction cycles. A hose reel with a

flexible rubber hose is mounted on the crosshead end of

the engine structure, with the hose connected to metal

tubing on the engine crosshead. As the crosshead

moves toward the fixed sheaves during arrestment, the

hose pays out and spring tension in the hose reel takes

up the hose during retraction. The spring tension on the

hose reel must be 9 pounds (±1/2 pound), with the hose

fully retracted, at all times.

The automatic lubrication controller (fig. 3-19)

allows the engine room operator to set both a pulse

counter and a timer unit which deliver a predetermined

amount of lubricant to every lubrication point. The

controller signals when the system is ready, when it is

operation or when a malfunction occurs. The controller

can be operated manually to initiate a lubrication cycle

without movement of the crosshead and cal reset itself

after a malfunction has been corrected in the lubrication

system.

The 28-inch pitch diameter sheave containing the

ball thrust bearing is not lubricated with the automatic

lubricating system. The ball thrust bearing eliminates

the need for constant lubrication. Lubricating the ball

thrust bearing sheave is accomplished with a manually

operated grease gun after every 20 to 30 arrestments.

(See fig. 3-18 for an illustration of the automatic

lubrication system.)

3-20

PRIMARY

DISTRIBUTION

BLOCK

(HIGH-SPEED)

(FIXED SHEAVE END)

LUBRICANT CONTROLLER

SECONDARY

DISTRIBUTION

BLOCKS

MASTER DISTRIBUTION

BLOCK ASSEMBLY

LUBRICANT

FILTER

LUBRICANT

PUMP

LUBRICANT

GREASE

DRUM

ISOLATION

SHUTOFF

VALVE

PRESSURE

REGULATOR

(CROSSHEAD END)

HOSE

REEL

SECONDARY

DISTRIBUTION

BLOCKS

PRIMARY

DISTRIBUTION BLOCK

(LOW SPEED)

SOLENOID

VALVE

ABEf0318

Figure 3-18.—Automatic lubrication system.