The cylinder and ram assembly constitutes the

actual engine of the arresting gear. It is located within

the engine structure between the movable crosshead

and the cylinder outlet elbow on the engines.

The

cylinder

is

a

machined,

forged

steel,

smooth-bore tube, open on both ends and large enough

to provide a working area for the ram and to house the

fluid necessary for aircraft arrestments. It is supported

within the engine structure by cylinder support saddles.

One end of the cylinder is clamped and bolted with four

cylinder clamps and Allen bolts to the cylinder outlet

elbow. The other end receives the ram

The ram is a large, hollow steel piston that is moved

in and out of the cylinder by the crosshead. It is bored to

reduce the weight, although it is not bored completely

through. The inner end (the end that fits in the mouth of

the cylinder) is solid and provides a working area

between the ram and engine fluid during arrestments.

The inner end of the ram contains a set of V-ring

packing to provide a seal for the engine fluid between

the cylinder wall and the ram also the inner end of the

ram is stepped to accommodate a cage and slippers,

which provide a bearing surface for the ram as it slides

in and out of the cylinder.

The outer (open) end of the hollow steel ram is

clamped into a socket on the crosshead by a split flange,

which fits into an annular groove near the end of the

ram.

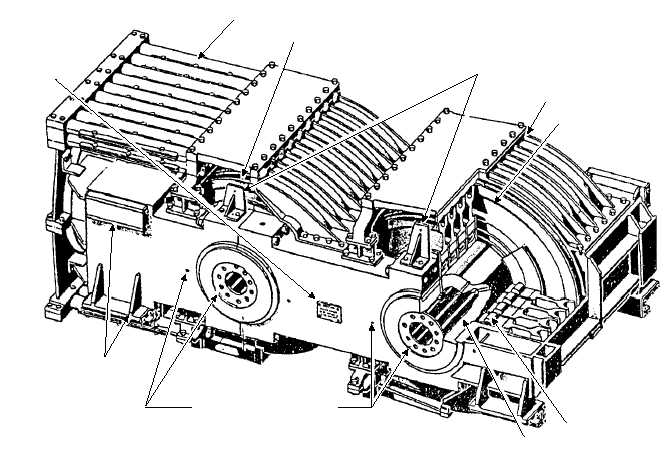

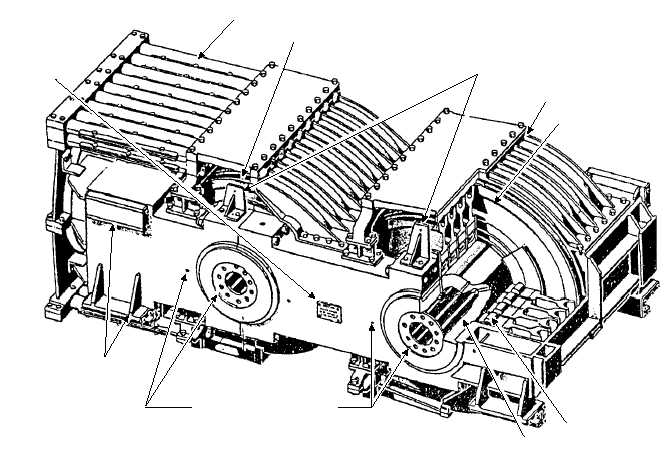

CROSSHEAD AND FIXED SHEAVE

INSTALLATION

The principle involved in the operation of the

crosshead and fixed sheaves is that of a block and

tackle. The purchase cables are reeved around the

sheaves of the crosshead and fixed sheave assemblies.

The crosshead is a three-piece welded structure with

two hollow steel shafts clamped between its outer

sections and the center section. The crosshead body is

clamped to the outer end of the ram by a split flange,

which fits into an annular groove around the end of the

ram. Figure 3-16 illustrates the crosshead.

The crosshead contains two similar banks of

sheaves, with nine sheaves in each bank. The sheaves

located outboard on the crosshead are 33-inch pitch

diameter, and the sheaves located on the inboard shaft

are 28-inch pitch diameter. The difference in the pitch

diameter of the two banks of sheaves is necessary so

that the purchase cable reeved around the outboard

3-18

CAUTION

PLATE

FAIRLEAD TUBES

SHEAVE (28” P.D.)

DEPTH GAUGE BRACKETS

FAIRLEAD

SHEAVE (33” P.D.)

ROLLER BEARING

SHAFT

SLIPPERS

LUBRICATION PORTS FOR

LUBRICATION SYSTEM

ABEf0316

Figure 3-16.—Crosshead assembly.