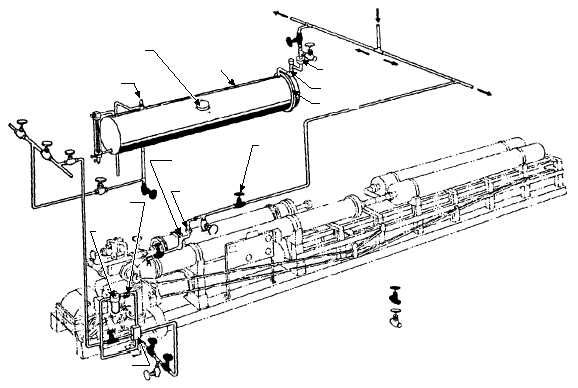

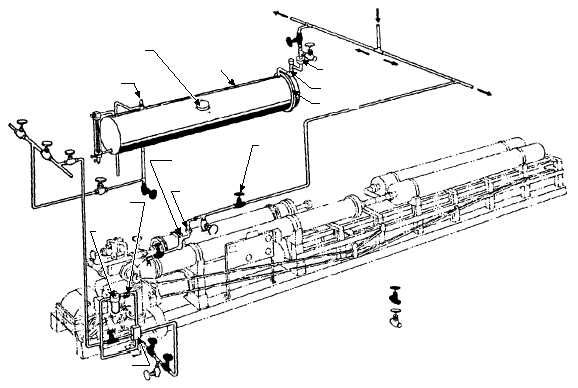

FLUID STOWAGE SYSTEM

A fluid stowage system (fig. 3-11) is provided to

stow fluid from the arresting engine during

maintenance and to transfer fluid back to the engine

after maintenance is complete. The fluid stowage

system consists of one common, steel stowage tank that

serves all the arresting engines installed on a particular

ship. It is equipped with piping valves from the

accumulator to the stowage tank.

The capacity of the fluid stowage tanks is 700

gallons. The stowage tank is capable of storing all the

fluid in the system of one arresting engine. Ship's

low-pressure air is used to force the fluid to and from

the stowage tank. A pressure relief valve, which is set at

120 psi, is provided to prevent excessive pressure

buildup. The relief valve is located on the stowage tank.

In addition, a 90-gallon stowage tank is installed on

each side for the port and starboard sheave damper

assemblies. The 90-gallon stowage tank is a repository

to transfer and replenish hydraulic fluid for the sheave

damper assemblies.

FLUID RECLAMATION SYSTEM

The fluid reclamation system (fig. 3-12) provides a

means of reclaiming hydraulic fluid removed from any

engine due to venting or through leaks or spills. The

fluid reclamation system consists of a stainless steel

90-gallon tank located in close proximity to the fluid

stowage tank, a centrifugal 1/3 hp pump, filter and

piping

connections.

The

piping

connects

the

reclamation tank to the existing stowage tank line.

During fluid transfer from the reclamation system,

hydraulic fluid is filtered to ensure that only clean

uncontaminated fluid enters the fluid stowage tank.

FLUID COOLER

During continuous arresting operations, the engine

fluid temperature rises because of friction of the fluid

moving through the engine, control valve, and piping.

To maintain extended pendant engine operation, the

fluid temperature is reduced by the fluid cooler. (See

fig. 3-13.) The maximum operating temperature for the

arresting engines is 170ºF. Prolonged operation at this

temperature limit is not recommended.

The fluid cooler is mounted in saddles on top of the

engine structure adjacent to the accumulator.

Fluid coolers are used on all Mk 7 arresting engines

serving a pendant engine. Engine fluid, as it is returned

from the accumulator to the main engine cylinder

during retraction of the engine, flows through the fluid

cooler body. Heat from the engine fluid is transferred to

cool service water (salt water) flowing at 100 gallons

per minute through tubes within the cooler body.

3-14

PRESSURE

RELIEF VALVE

(SET AT 120 PSI)

MANHOLE

COVER

700-GALLON

TANK

CHECK

VALVE

FILTER

316077-2

AIR STRAINER

MOISTURE

SEPARATOR

MAIN AIR

SHUTOFF

VALVE

TO OTHER

ENGINES

MOISTURE

SEPARATOR

AIR STRAINER

TO OTHER

ENGINES

FROM LOW-PRESSURE

AIR SUPPLY

LEGEND

CLOSED VALVE

OPEN VALVE

PLUG COCK

FLANGE

ABEf0311

Figure 3-11.—Fluid stowage system—secured condition.