bolted to the air expansion flask manifold. The fluid

end of the accumulator is flanged and bolted to the

accumulator nozzle, which contains a fluid-level

indicator, a device used to indicate to the engine-room

operator whether the system has the proper amount of

fluid. The fluid indicator registers the following three

conditions—DRAIN (excessive amount of fluid in the

system), BATTERY (proper amount of fluid in the

system), and FILL (insufficient amount of fluid in the

system).

The floating air-fluid separator piston is made of

aluminum alloy and has two sets of V-ring packing (one

for the air side and one for the fluid side), which prevent

air from leaking past the piston into the fluid side of the

accumulator, or fluid from leaking into the air side. Two

slipper cages with phenolic slippers are fitted onto the

piston to act as a bearing surface between the piston and

the cylinder wall. The phenolic slippers are replaceable

and must be replaced when the maximum allowable

wear has been reached. This is to prevent

metal-to-metal wear between the piston and the

accumulator wall. An eyebolt is provided on the air side

of the piston to aid in removing the piston from the

accumulator when maintenance is required. The fluid

side of the piston has a striker rod that actuates a

fluid-level indicator located in the accumulator nozzle.

The fluid-level indicator has a drive shaft that

extends through the nozzle from side to side and is

secured in place by flanges and bolts. O-rings provide a

seal against leakage of fluid around the drive shaft.

Gears are secured onto the shaft inside the nozzle.

These gears mate with teeth on the actuator rod, which

extends fore and aft in the nozzle, and the

fluid-indicator rod, which is vertical and extends

through the top of the nozzle. An O-ring prevents

leakage around the indicator rod. When the striker rod

on the piston makes contact with the actuator rod, the

drive shaft rotates, causing the indicator rod to move

down. See figure 3-9.

An indicator plate is mounted on top of the nozzle.

The plate has the readings DRAIN, BATTERY, and

FILL. The indicator rod is a differential rod; and any

time the piston striker rod is not in contact with the

actuator rod, accumulator pressure working on the

differential area of the indicator rod will cause the

indicator rod to rise to the DRAIN position. The engine

crosshead must always be in its BATTERY position

when the fluid level of the arresting engine is checked.

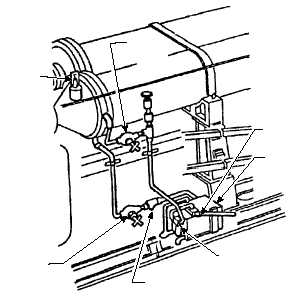

FLUID REPLENISHMENT

SYSTEM

LEARNING OBJECTIVE: Describe the

components of the fluid replenishment system.

In any hydraulic system, small amounts of fluid are

lost due to leakage. Fluid also contracts when cold and

expands when hot. To compensate for leakage and

expansion or contraction of the hydraulic fluid in the

hydraulic system of the Mk 7 arresting engines, a fluid

replenishment system is provided. See figure 3-10.

The fluid replenishment system consists of a small

hand pump, mounted on the lower engine frame that is

connected by piping to the engine accumulator and a

6-gallon stowage tank. If, because of leakage or fluid

contraction while the engine crosshead is in BATTERY,

the fluid-level indicator reads FILL, the supply valve in

the piping is opened and the hand pump is operated

until the indicator reads BATTERY. A fluid filter is

located in the supply line to filter the fluid being

pumped into the accumulator. If the fluid-level

indicator reads DRAIN, the return valve located in the

return line is opened, and fluid from the accumulator

drains into the replenishment tank. When the fluid-level

indicator reads BATTERY, the return valve is closed.

3-13

VALVE

(RETURN)

STRAINER

FILTER

TANK

HAND

PUMP

FLUID

LEVEL

INDICATOR

VALVE

(SUPPLY)

ABEf0310

Figure 3-10.—Fluid replenishment system.