this case the initial valve opening is maximum. If the

ratio is 4:1, however, the valve sleeve rises only

one-fourth the distance that the plunger moves. In this

case the initial valve opening is minimum.

The lever setting may be adjusted to any setting

within the two extremes previously discussed; the

particular setting used is dependent upon the weight of

the aircraft to be arrested. The weight setting is made

with the engine in battery position prior to landing the

aircraft.

Adjustment of the setting determines the position

of the valve sleeve. Therefore, it also sets the amount

the valve will open at the beginning of the arrestment

stroke. Similarly, it determines the rate of closure

during the stroke so that the valve will always seat at the

same runout.

The valve stem sleeve allows a relatively unloaded

and cushioned opening at the beginning of the stroke.

The lever system, if set for a heavy aircraft, reduces

the allowable valve stem opening and thus increases the

resistance of the valve to the flow of fluid. The energy

of the aircraft is dissipated by forcing fluid through the

restricted valve opening.

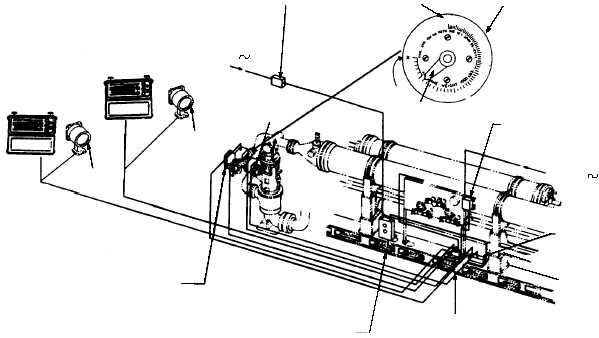

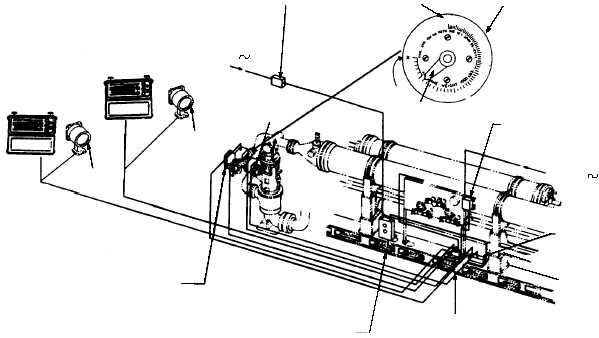

ELECTRICAL SYSTEM

The electrical system provides, controls, and

safeguards the distribution of electrical energy to the

weight selector motor and the synchro indicators. The

electrical circuits (fig. 3-5) are the control valve weight

selector circuit and the indicator circuit.

AIRCRAFT WEIGHT SELECTOR SYSTEM

AND ELECTRICAL CIRCUIT

Due to the varying weights and landing speeds of

carrier-based aircraft, it is necessary to vary the initial

opening of the CROV and have a smaller initial opening

for heavier aircraft than for lighter aircraft. The

variation of the setting of the CROV is the function of

the aircraft weight selector motor unit. (See fig. 3-5.)

Normally, the settings are made electrically by

depressing an increase or decrease push button located

at the control valve. The settings can also be

accomplished manually by a handwheel at the control

valve.

The aircraft weight selector is motor operated from

the 440-volt, 60-hertz, 3-phase ship's power supply. A

fused switch box or breaker is provided to energize or

de-energize the control circuit. To increase and

decrease settings, the direction of the aircraft weight

selector motor rotation is controlled by the motor

controller. Should an electrical failure occur, the

settings can be made manually by pulling out on the

handwheel and turning in either the increase or the

decrease direction.

Settings on the aircraft weight selector are

monitored locally at the control valve motor unit dial

and remotely by synchro receivers located at Pri-Fly

and the deckedge control station.

3-8

FUSED SWITCH BOX

FUSED SWITCH BOX

AWIS

DECKEDGE

STATION

AWIS AT

PRI-FLY

CONTROL

STATION

SYNCHRO

SYNCHRO

MINIMUM

SETTING

MAXIMUM

SETTING

POINTER

ASSEMBLY

ENGINE 440V

TERMINAL BOX

MOTOR CONTROLLER

AIRCRAFT WEIGHT

SELECTOR MOTOR

UNIT , 440V

ABE30305

12

20

30

40

50

60

70

AIRCRAFT WEIGHT

SELECTOR DIAL

INDICATOR CIRCUIT

POWER SUPPLY

110V, 60

, 10

MOTOR CIRCUIT

POWER SUPPLY

400V, 60

, 30

ENGINE 110V

TERMINAL BOX

AIRCRAFT WEIGHT

SELECTOR PUSHBUTTON

STATION

Figure 3-5.—Aircraft weight selector system.