When the operator pulls down on the retracting

lever, the force transmitted through the control cable

lifts the end of the retracting lever that is attached to the

return spring and tie rod. The retracting lever has a pivot

point on the block mounting of the valve. As the one

end of the retracting lever is lifted, the end connected to

the plunger pushes down on the plunger and valve stem,

allowing fluid flow through the valve from the

accumulator or fluid cooler to the engine cylinder, thus

forcing the ram and crosshead back to their battery

position. After retraction is complete, the retracting

lever is released and the return spring pulls down on the

retracting lever, which in turn pulls up on the plunger

and valve stem, which closes the valve. See figure 3-7.

The ideal condition is that tension be kept on the

purchase cable from the beginning of the retracting

stroke until the ram is in its battery position. An

interruption of the stroke generally disrupts this

condition and creates cable backlash, which results in

cable slack on the engine.

If an emergency arises involving the safety of

personnel or equipment, and an interruption of

full-speed

retraction

is

necessary,

the

following

procedures are recommended to prevent possible

damage, such as a tight kink, to the purchase cable:

1.

Resume retracting very slowly at first to rid the

cable system of slack.

2.

Resume full-speed retraction only after the

cable slack has been eliminated and the cable

has tension.

3.

Inspect sheave damper sheaves for proper

seating of the purchase cable on completion of

retraction.

A

shock

absorber

like

the

one

found

on

automobiles is installed on the operating lever to

eliminate chattering of the retracting valve during

closing.

ACCUMULATOR SYSTEM

LEARNING OBJECTIVE: Describe the

accumulator system.

The Mk 7 Mod 3 arresting engine has a

recirculating-type hydraulic system. During arrest-

ment, the hydraulic fluid is forced from the main engine

cylinder, through the CRO valve, to the accumulator.

An initial air charge of 400 psi in the accumulator

builds up to approximately 650 psi during arrestment.

This increased pressure is used to force the fluid from

the accumulator into the fluid cooler, thus forcing fluid

from the previous arrestment, already cooled by the

cooler, out of the cooler, through the retracting valve,

and into the main engine cylinder, returning the engine

to its BATTERY position.

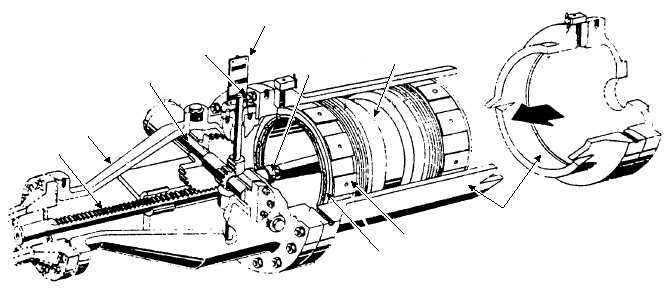

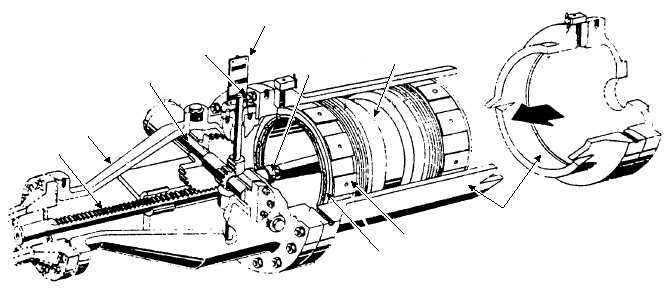

The accumulator (fig. 3-9) is a long, steel cylinder

mounted horizontally in saddles on the engine

structure, with the fluid end toward the fixed sheaves.

Inside the accumulator is a floating piston that

separates the air side of the accumulator from the fluid

side. The air end of the accumulator is flanged and

3-12

ROD

NOZZLE

SHAFT

FLUID INDICATOR ROD

PISTON

RETAINER RING

SLIPPER AND CAGE ASSEMBLY

CYLINDER

A

STOP

LEVEL INDICATOR PLATE

ABEf0309

Figure 3-9.—The Mk 7 accumulator.