Using a short piece of seizing wire thoroughly

degreased, pierce the bubbles that rise to the surface of

the hot top. Do not poke the wire into the zinc more than

1/2 inch. Skim the surface of the hot top with the end of

the seizing wire to allow the gas bubbles to rise and be

accessible for piercing.

After the zinc has solidified, allow the poured

terminal to air-cool at room temperature for 30 minutes.

During this time the zinc will harden. After the cooling

period, proceed as follows:

1.

Remove the textile cloth and plaster the

terminal.

2.

Pour 4 gallons of preservative oil into a clean

5-gallon metal container.

3.

With the preservative oil at room temperature,

immerse the entire poured terminal for 30

minutes. This will rapidly cool the terminal.

4.

Immediately after the 30-minute oil quench

period, remove the terminal and allow the

excess oil to drain into the container.

5.

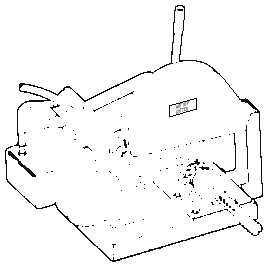

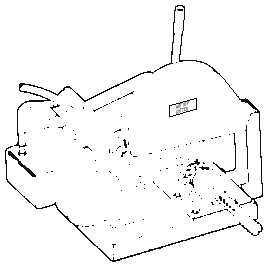

Using the hot-top cutter assembly, cut off the

hot top flush with the top of the terminal after

the terminal has cooled (fig. 3-60).

Finishing and Inspecting the Terminal

Round off the sharp edges of the terminal with a

file. File the zinc down to a smooth surface flush with

the end of the terminal. Clean the terminal with a wire

brush. Remove all traces of residual flux, plaster, and

superficial rust (using the wire brush) from the wire

rope for a distance of 6 inches from the base of the

terminal. Chase the threads with an applicable

threading die.

Inspect the zinc face of the terminal for soundness

of zinc and good wire distribution. The presence of any

cavities in the face of the zinc indicates that the strength

of the terminal is questionable. The criteria for

acceptance of cavities are as follows:

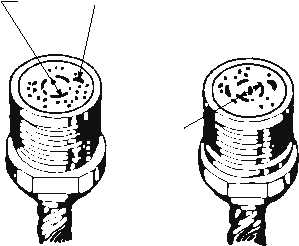

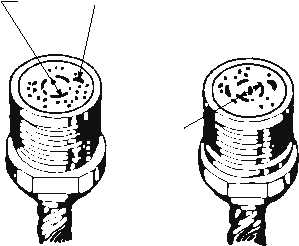

1.

A maximum of five cavities up to 1/32-inch

wide and 1/32-inch deep scattered randomly

over the zinc face. Figure 3-61, view A,

3-55

ABEf0360

Figure 3-60.—Cutting the hot top.

1/32 WIDE X 1/32 DEEP CAVITY

(MAX OF 5)

ACCEPTABLE

UNACCEPTABLE

UNACCEPTABLE

ACCEPTABLE

3/4 DIA

1/8 WIDE X 1/8 DEEP CAVITY

(MAX OF 1)

3/4 DIA

CONDITION A

CONDITION B

ABEf0361

Figure 3-61.—Inspection of zinc face.