illustrates an acceptable face. Crop and repour

if six or more cavities are found.

2.

A cavity up to 1/8-inch wide and 1/8-inch deep

caused by breaching of several wires must

NOT be in the center of the zinc face within the

area of 3/4-inch diameter. An acceptable face is

shown in view B. A 1/8-inch cavity by 1/8-inch

cavity caused by any other factor than

breaching

wires

is

not

acceptable.

This

breaching is several wires coming together at

the surface, which does not permit the zinc to

fill the area. These allowable cavities are the

result of pouring, and not that of a pull test.

Inspect around the base of the terminal for a

penetration of zinc. This penetration must be present to

have an acceptable terminal. It is also a good indication

of a well-poured terminal. The wires of the strands of

the wire rope below the terminal must not show any

deformity due to having been held too tightly in the vise

during the pouring and finishing operations.

Testing the Terminal

During an arrestment, the wire rope system must

take a very high impact load; therefore, all fittings of

the system must be carefully poured. It is imperative

that the fitting be strong and well made. To determine

their condition and strength, the terminals must be

tested for soundness of the poured joint.

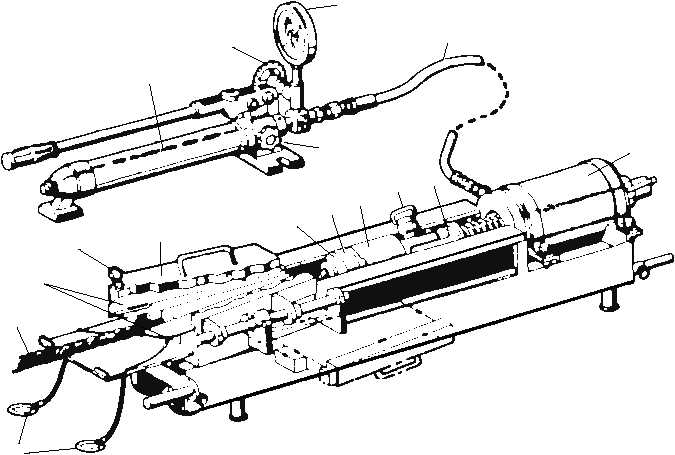

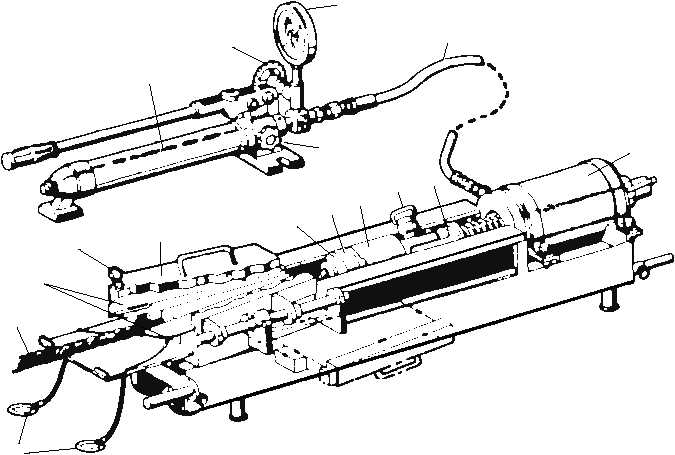

Terminals poured by a naval activity or by

personnel aboard ship are tested for reliability. The

cable terminal proof-loading machine is a self-

3-56

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

ABEf0362

1. Wedge set

2. Safety lock pin

3. Grip assembly lid

4. Retracting cables

5. Tension gauge

6. Hand hydraulic pump

7. Hose assembly

8. Ram (cylinder)

9. Connecting pin

10. Clevis socket

11. Lock ring

12. Cable terminal

13. Tension rod

14. Purchase cable

15. Needle valve

16. External load release valve

Figure 3-62.—Wedge-type proof-loading machine (single ram).