switch to shutoff the power to the hoist motor and

electric brake. Loss of electric power causes the brake

to automatically stop the elevator. If the brake fails to

stop the elevator, the governor sheave grips the

governor rope, causing the broken-rope safety device to

stop the elevator.

A slack, cable sensing, safety device is provided for

each suspension rope and the governor rope. Located in

the area between the winch drums and the overhead

sheaves,

these

devices

function

by

applying

a

spring-loaded follower roller to the wire rope. Rope

slack causes a proximity switch to shutoff electrical

power to the hoisting winch motor and brake, which

stops the elevator.

If the elevator over travels upward beyond the

maximum up stop position, an over travel limit switch

is actuated. This stops the elevator by shutting off

power to the hoisting winch motor and brake.

If the elevator over travels downward beyond the

hold deck loading station level, spring bumpers in the

bottom of the elevator trunk stop the platform. The

slack-cable switches are actuated to cut off power to the

hoisting winch motor and brake.

An operator-attended control panel is located next

to all elevator doors. All operator control panels have a

display of selector switches, push buttons, and indicator

lamps suited for the control functions required at the

station served. All control panels have an emergency

stop-run switch from which all operations of the

elevator can be stopped.

The main operator control panel and electrical

power switch are located at the 2nd deck-level station.

An elevator can be dispatched to another level from any

operator control panel. The lower-stage elevator control

system can dispatch the elevator to another level.

However, it can't retrieve the elevator from another

level.

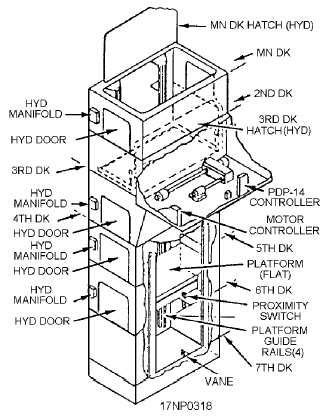

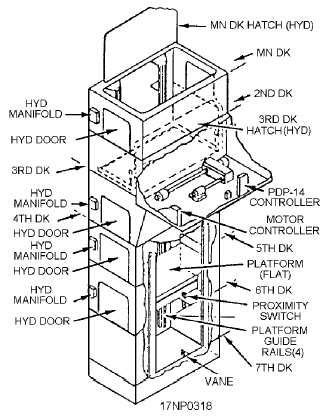

IMPROVED WEAPONS HANDLING SYS-

TEM

(IWHS)

LOWER-STAGE

WEAPONS

ELEVATORS.—The IWHS lower-stage weapons

elevator

(fig.

11-11)

services

magazines

and

ammunition handling areas from the 7th deck level up

to and including the main deck (hangar deck). The

IWHS is a highly sophisticated system controlled by a

PDP-14 programmable controller that continually

tracks the location of the platform to within one-twelfth

of an inch. Because of the complexity of the IWHS,

elevator operators and maintenance personnel are

extensively trained in hydraulics, electricity, and

electronics.

Four cables attached at the corners lift the platform.

The platform machinery is located at the 3rd deck level.

The hatches are opened hydraulically. They are

designed

to

automatically

undog-open-latch

and

unlatch-close-dog. The elevator doors are also operated

hydraulically.

The IWHS incorporates the following safety

features:

An over speed governor slack-cable device

An over speed governor device

A hydraulic interlock to prevent two hatches

from being opened at the same time

A hydraulic interlock to prevent hatches from

closing when dogs are in the dogged position

An electrical interlock to prevent opening a

magazine door unless the platform is at that level

An electrical interlock to prevent opening more

than one magazine door at a time

A pressure switch to prevent operation of the

elevator when the hydraulic pressure is below

1,200 psi

11-19

Figure 11-11.—Typical IWHS lower-stage, weapons elevator.