The name of the testing activity and the name of

the person performing the test.

The date the test was performed.

The date of the next required inspection may be

included, if desired.

If the test period has expired or if documentation is

not available to verify the latest load test status, the

equipment is tested before it is used. If the equipment

fails the load test specifications, the equipment is

destroyed or, if economically feasible, repaired.

REVIEW NUMBER 2 ANSWERS

A1.

Missile magazines are vented to the

atmosphere.

A2.

Mk 58 marine location markers shouldn't be

stowed in magazines that are equipped with

sprinklers.

A3.

In a shipboard magazine, the FH circuit

indicates a rapid rise in temperature.

A4.

Mk 3 or Mk 12 metal pallets are used as

magazine stowage dunnage aboard ship.

A5.

NAVSEASYSCOM should be notified if the

temperature in any magazine is consistently

above 100ºF.

A6.

The ship's gunner controls all magazine keys

aboard ship.

Weapons Elevators

There are currently more than 150 weapons

elevators, involving over 55 different designs, installed

on aircraft carriers. The size, type, and location of these

weapons elevators will vary among the different classes

of aircraft carriers.

The following text contains a brief description of

the

two

major

classifications

(lower-stage

and

upper-stage) of weapons elevators. Regardless of the

type of installation, a weapons elevator provides a safe

and efficient means for you to handle weapons and

weapons components among the magazines and the

various assemblies, staging, and arming areas within

the ship.

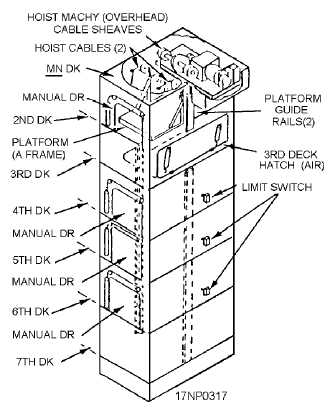

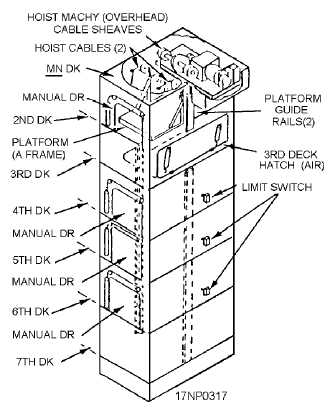

LOWER-STAGE

WEAPONS

ELEVATORS

(5,500 POUNDS).—The 5,500-pound, lower-stage,

weapons elevator (fig. 11-10) services magazines and

ammunition handling areas from the 7th-deck level up

to and including the 2nd-deck level. The components of

the

elevator

include

an

electrically

powered,

multiple-drum winch, an elevator platform, and an

enclosed, watertight, vertical trunk with doors located

at the levels and stations serviced, and a semiautomatic

control system.

Ramps are used to bridge the gaps in the door

opening between the elevator platform and the deck.

These allow you to load or unload the elevator platform

by using forklift trucks or wheeled skids.

Each lower-stage elevator is equipped with a

broken-rope safety device, an over speed governor

device,

and

slack

cable-sensing

devices.

The

broken-rope safety device is mounted on the elevator

platform assembly. If any one of the platform

suspensions ropes break, a roller-wedging mechanism

automatically operates to lock the platform to the guide

rails.

A counterweight-type governor device for limiting

speed of elevator down travel is located in the upper end

of the elevator trunk. The governor is operated by a wire

rope connected to a lever of the broken-rope safety

device on the elevator platform. Then, the rope is

passed over the governor sheave and attached to the

governor spooling drum on the hoisting winch.

Excessive down speeds causes the governor limits

11-18

Figure 11-10.—Typical 5,000-pound, lower-stage, weapons

elevator.