CHAPTER 4

AIRCRAFT METALLIC REPAIR

Tools should not be placed on finished parts or

INTRODUCTION

machines.

Before performing aircraft metallic repair, you

There are many different types of hand tools used

must be familiar with the tools, special equipment,

for aircraft metallic repair and sheet metal fabrication.

terms, and techniques used to accomplish this type of

In the following text, we will discuss a few of the more

maintenance. In the following text, we will discuss

common types used for sheet metal fabrication. For a

these subjects and basic sheet metal fabrication

more detailed explanation of all of the various hand

procedures as well as several different types of aircraft

tools associated with aircraft metallic repair and sheet

structural metallic repair procedures. Before you

metal fabrication, refer to Use and Care of Hand Tools

perform any type of structural repair to an aircraft,

and Measuring Devices, NAVEDTRA 14256.

always consult the applicable aircraft Maintenance

Instruction Manual (MIM).

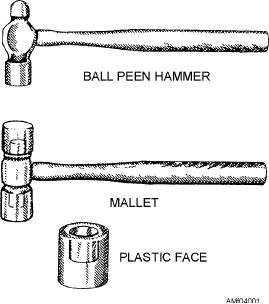

Hammers

STRUCTURAL TOOLS

Hammers are used to apply a striking force where

the force of the hand alone is insufficient. Each of the

LEARNING OBJECTIVE: Identify the var-

hammers discussed in this section is composed of a

ious structural tools used for sheet metal

head and a handle, even though these parts differ

fabrication. Identify the various structural tools

greatly from hammer to hammer.

used for aircraft structural repair.

BALL PEEN HAMMER.--The ball peen

You should always have a thorough knowledge of

hammer is sometimes referred to as a machinist's

the tools of your trade. This will enable you to increase

hammer. It is a hard-faced hammer made of forged tool

the quality of maintenance on your squadron's aircraft.

steel. See figure 4-1.

One of the most important skills that you can have is the

ability to use the tools that are required to complete any

The flat end of the head is called the face. This end

given task in a timely and professional manner. These

is used for most hammering jobs. The domed end of the

tools include various hand tools, power tools, drills, and

hammer is called the peen. The peen end is smaller in

special tools.

diameter than the face, and is useful for striking in areas

that are too small for the face to enter.

HAND TOOLS

Before discussing the tools individually, a few

comments on the care and handling of hand tools are

appropriate. The condition in which you maintain your

tools determines your efficiency as well as how your

superiors view your day-to-day work.

Each mechanic should keep all assigned tools in the

toolbox when they are not being used. Every tool

should have a place, and every tool should be kept in its

place. All tools should be cleaned after every use and

before being placed in the toolbox. If they are not to be

used again the same day, they should be oiled with a

light preservative oil to prevent rusting. Tools that are

being used at a workbench or at a machine should be

kept within easy reach of the mechanic, but should be

kept where they will not fall or be knocked to the deck.

Figure 4-1.--Hammers.

4-1