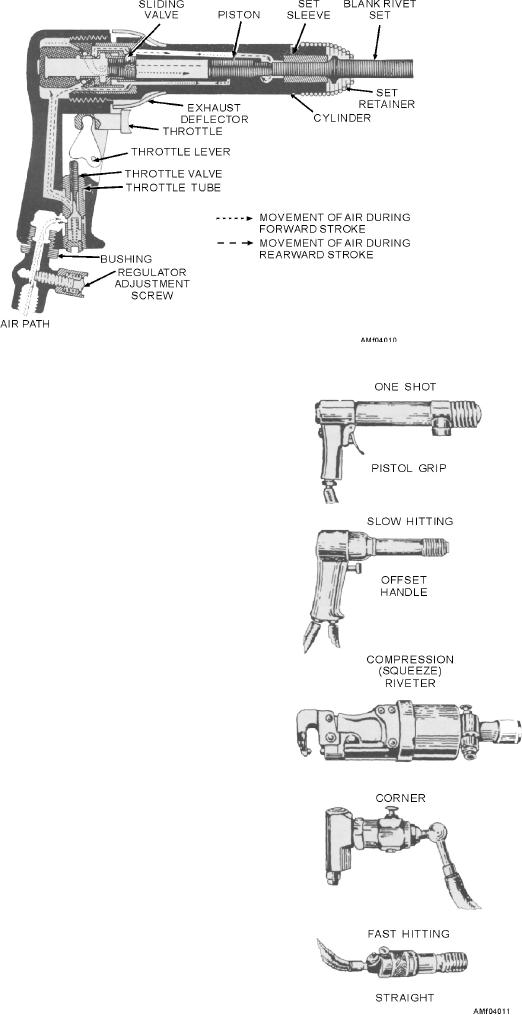

Figure 4-10.--Rivet gun internal airflow.

See figure 4-10. Regulated air entering the gun passes

through the handle and throttle valve, which is

controlled by the trigger, and into the cylinder in which

the piston moves. Air pressure forces the piston down

against the rivet set and exhausts itself through side

ports.

The rivet set recoils, forcing the piston back. Then

the cycle is repeated. Each time the piston strikes the

rivet set, the force is transmitted to the rivet. Rivet sets

come in various sizes to fit the various shaped rivet

heads. Rivet set retainer springs must be used on all

pneumatic rivet sets to prevent the set from being

discharged from the gun when the trigger is pulled.

Several types of pneumatic riveters are in general

use. They are the one-shot gun, slow-hitting gun,

fast-hitting gun, corner riveter, and the squeeze riveter.

See figure 4-11. The type of gun used depends on the

particular job at hand, with each type having its

advantages for certain types of work. One person can

rivet small parts if the part is accessible for both

bucking and driving. The greater part of riveted work,

however, requires two people.

Rivet Guns

The size and the type of gun used for a particular

job depend upon the size and alloy rivets being driven

and the accessibility of the rivet. For driving

medium-sized, heat-treated rivets that are in accessible

places, the slow-hitting gun is preferred. For small, soft

alloy rivets, the fast-hitting gun is preferable. There will

be places where a conventional gun cannot be used. For

this type of work, a corner gun is employed.

Figure 4-11.--Various types of rivet guns.

4-6