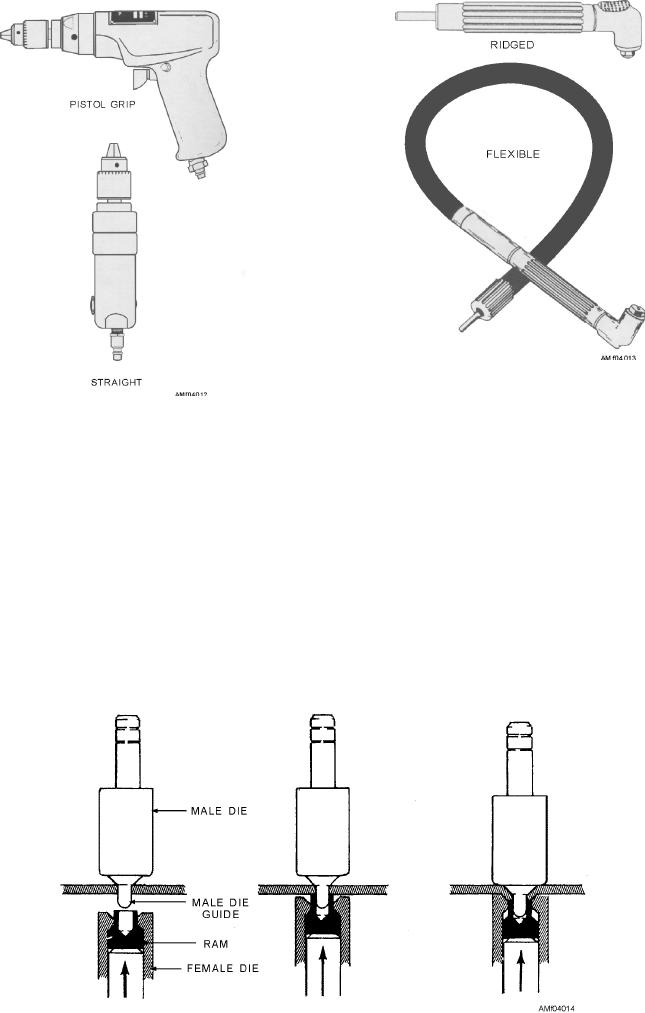

Figure 4-13.--Angle-drive drills.

chuck normally requires a wrench to tighten the jaws or

Figure 4-12.--Pneumatic drills.

it may require a special threaded drill bit.

into the air supply. The two most used types are the

straight and the pistol grip. See figure 4-12.

SPECIAL TOOLS

Angle-Drive Drills

Special tools are not normally part of an

individual's toolbox. These tools are normally

The angle-drive drills are attached to the drill motor

maintained in a central tool room and signed out when

by an adapter assembly or clamped into the existing

needed.

drill chuck. They are available with a ridged or flexible

drive shaft and come in several different head angles.

Dimple Countersinking Tools

See figure 4-13. These units are designed to be used as

Dimple countersinking is accomplished by using

an extension of the drill motor in hard to reach areas.

male and female dies. The female die, shown in figure

The drill motor should never be started unless you have

4-14, contains a spring-loaded ram that flattens the

positive control of the angle-drive unit. The flexible

bottom of the dimple as it is formed. This prevents

shaft is commonly referred to as a snake drill. The drill

Figure 4-14.--Dimple countersinking.

4-8