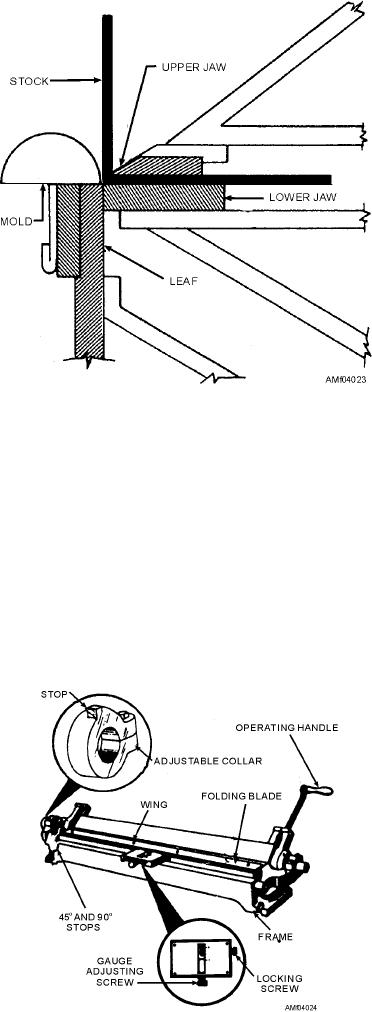

Figure 4-23.--Cornice brake with mold and stock.

metal that is ready to be formed over a mold attached to

It can be adjusted to handle a variety of metal

a cornice brake.

thicknesses and to bend metal to a variety of radii.

The brake is equipped with a stop gauge, which

BAR FOLDER.--The bar folder, shown in figure

consists of a rod, a yoke, and a setscrew. The stop gauge

4-24, is designed for use in making bends or folds along

limits the travel of the bending leaf. This feature is used

edges of sheets of metal. This machine is best suited for

to make a number of pieces with the same angle of

folding small hems, flanges, seams, and edges to be

bend.

wired. Most bar folders have a capacity for metal up to

22 gauge in thickness and 42 inches in length. Before

The standard cornice brake is extremely useful for

using the bar folder, you must make several

making single hems, double hems, lock seams, and

adjustments, including adjustments for thickness of

various other shapes, some of which require the use of

material, width of fold, sharpness of fold, and angle of

molds. The molds are fastened to the bending leaf of the

fold.

brake by friction clamps. Figure 4-23 shows sheet

Figure 4-24.--Bar folder.

4-13