Q4-13.

The combination of bending and stretching of

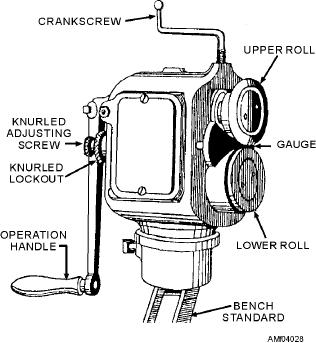

Rotary Machine.--The rotary machine, shown in

metal, using male and female dies, forms

figure 4-28, is used on cylindrical and flat sheet metal to

what type of countersink?

shape the edge or to form a bead along the edge.

Various shaped rolls can be installed on the rotary

Q4-14.

Why is it necessary to use a hot dimpling

machine to perform these operations.

process for aluminum alloys?

Q4-1. A soft-faced hammer is known by what name?

Q4-15.

Portable power-operated snips are more

commonly referred to by what name?

Q4-2. When rivets are too long for repair, you can

size them to the correct length with what tool?

Q4-16.

What sheet metal equipment would you use to

fabricate a wire edge?

Q4-3. What must you use to form a bucktail on a

rivet?

Q4-17.

What brake has removable steel fingers of

varying widths?

Q4-4. Locally manufactured bucking bars are

normally made from what type of steel?

SHEET METAL FABRICATION

Q4-5. To transfer hole locations from the airframe

or skin to a patch, you should use what tool?

LEARNING OBJECTIVE: Recognize the

terms associated with the fabrication of sheet

Q4-6. What is the color of a 1/8-inch Cleco

metal parts. Identify the various procedures

fastener?

used in the fabrication of sheet metal parts.

Q4-7. What is the difference between snips and

To effectively construct and repair parts of an

shears?

airframe, you must be able to lay out, cut, and form

Q4-8. What are the five types of pneumatic riveters?

metal. The layout of bend lines must include the

allowance for the amount of material used to make the

Q4-9. What rivet gun is generally used for heavy

bend in the proper location. The proper fit of the

hitting, and under suitable conditions, is the

finished part can be ensured if the layout, cuts, and

fastest method of riveting?

bends are carefully considered before the actual

Q4-10.

What will happen if you apply too much

fabrication is started. The procedures and equipment

pressure to the drill?

discussed in this chapter are designed to provide

Q4-11.

Most pneumatic drills are powered by what

accurate and dependable results.

type of motor?

The development of a layout on sheet metal is

Q4-12.

A flexible shaft drill is also known by what

basically the same as the development of blueprints and

other name?

drawings. For a better understanding of these

procedures, you should refer to Blueprint Reading and

Sketching, NAVEDTRA 14040.

LAYOUT PROCEDURES

When you are laying out metal, there are certain

precautions that should be observed. In the following

paragraphs, some of the more important precautions are

discussed. For information on the use of layout tools,

you should refer to Use and Care of Hand Tools and

Measuring Tools, NAVEDTRA 14256.

You should take every precaution to avoid marring

aluminum-alloy and steel sheets. To protect the under

surface of the material from any possible damage, you

should place a piece of heavy paper, felt, or plywood

between the material and the working surface. When

you are working with a large sheet of material, it is

important to avoid bending it. It is a good idea to have

someone help you place it on the work surface.

Figure 4-28.--Rotary machine.

4-15