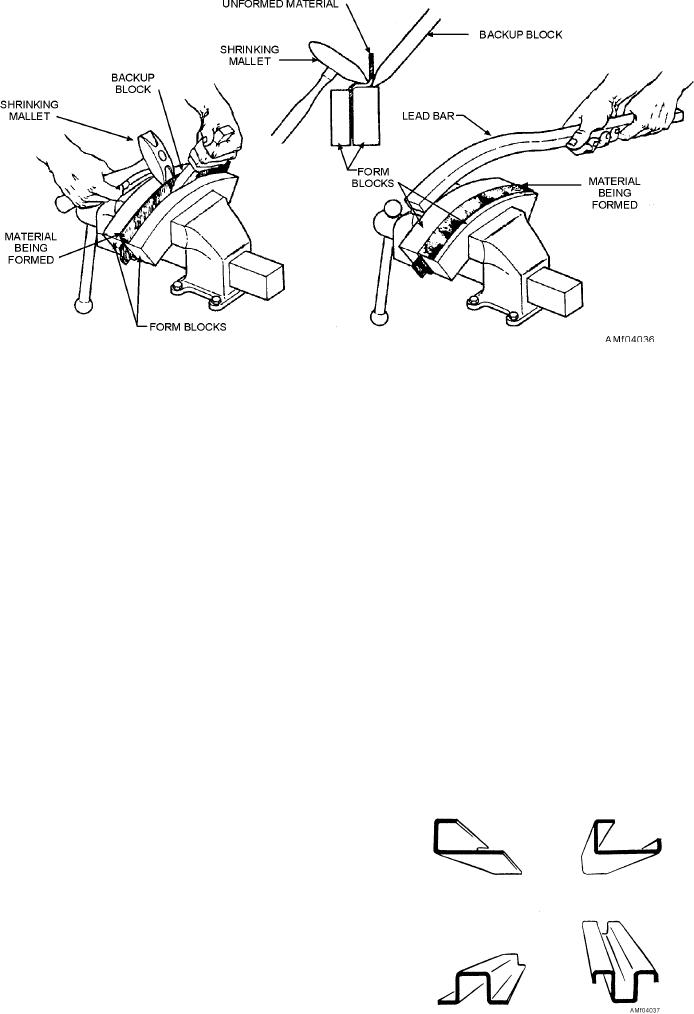

Figure 4-36.--Forming convex hand bends.

Bending on a Brake

rounded face to start hammering at the extreme ends of

the part, and then continue toward the center of the

The easiest and most accurate method of making

bend. This procedure permits some of the material at

straight-line bends in a piece of sheet metal is to use a

the ends of the part to be worked into the center of the

box and pan brake or a cornice brake. The use of these

curve where it will be needed. Continue hammering

brakes is relatively simple. However, if they are not

until the metal is gradually worked down over the entire

used correctly, the time and the work involved in

flange and flush with the form block. After the flange is

computing the bend allowance and laying out the job,

formed, trim off the excess material and check the part

as well as the metal, are wasted. Before you bend any

for accuracy.

work that must have an accurate bend radius and

Convex surfaces are formed by shrinking the

definite leg length, the brake settings should be checked

material over a form block. See figure 4-36. You should

with a piece of scrap metal. To make an ordinary bend

use a wooden or plastic shrinking mallet and a backup

on a brake, you should place the sheet to be bent on the

or wedge block to start hammering at the center of the

bed so that the bend line is directly under the upper jaw

curve, and then work toward both ends. Hammer the

or clamping bar. Then, pull down the clamping bar

flange down over the form by striking the metal with

handle. This brings the clamping bar down to hold the

glancing blows at an angle of approximately 45

sheet firmly in place. Next, set the stop for the proper

degrees. You should use a motion that will tend to pull

angle or amount of bend. Finally, make the bend by

the part away from the radius of the form block. The

raising the bending leaf until it strikes the stop. If more

wedge block is used to keep the edge of the flange as

than one bend is to be made, bring the next bend line

nearly perpendicular to the form block as possible. The

under the clamping bar and repeat the procedure. See

wedge block also lessens the possibility of buckling,

figures 4-22 and 4-25.

splitting, or cracking the metal.

Another method of hand forming convex flanges is

to use a lead bar or strap. The material, which is secured

in the form block, is struck by the lead strap. The strap

takes the shape of the part being formed and forces it

down against the form block. One advantage of this

method is the metal is formed without marring or

wrinkling and is not thinned as much as it would be by

other methods of hand forming. This method is also

illustrated in figure 4-36. After the flange is formed by

either method, trim off the excess material and check

Figure 4-37.--Types of bends on a bar folder.

the part for accuracy.

4-20