securely together. It is important that the sheets be held

Locations for the rivet holes should be center

firmly together near the area of the rivet being driven.

punched and the drilling done with a power drill, either

electric or pneumatic. Electric drills constitute a fire

To adjust the speed of the gun, place it against a

hazard when you are drilling on or near an aircraft. The

block of wood. Never operate a rivet gun without

hazard is caused by the arcing of the brushes.

resistance against the set. The vibrating action may

Therefore, the pneumatic drill should be used. The

cause the retaining spring to break, allowing the set to

center punch mark should be large enough to prevent

fly out.

the drill from slipping out of position, but must not be

made with enough force to dent the surrounding

material. All burrs must be removed by using a larger

WARNING

size drill or by using a deburring tool.

A rivet set can be a deadly weapon. If a rivet set is

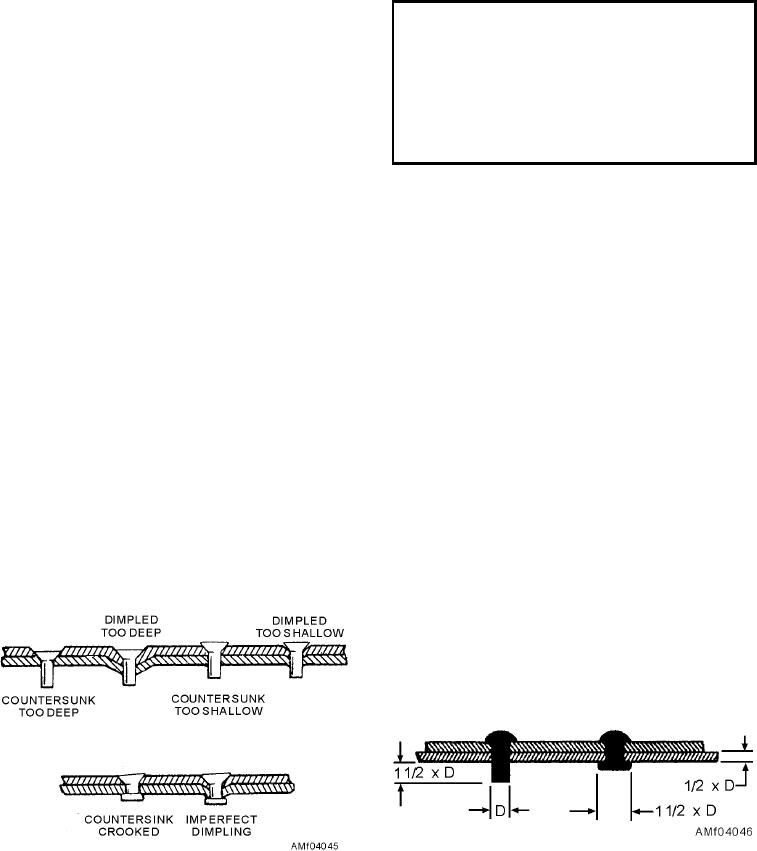

Flush Riveting

placed in a rivet gun without a set retainer and the

throttle of the gun is opened, the rivet set may be

In aircraft construction, manufacturers are

projected like a bullet. This may cause severe injury

eliminating protruding-head rivets on the exterior

to a person or destruction of equipment.

surfaces. In fabricating stressed metal skin, all exposed

rivet heads must be countersunk to lie flush with the

The gun should be adjusted so the rivet can be

outer surface of the skin. It is essential to provide an

driven in the shortest possible time, but you must take

aerodynamically smooth surface. See figure 4-45.

care not to drive the rivet so hard or in such a manner as

Flush rivets are more difficult to install because the

to dimple the metal. Practice will enable you to

parts being riveted must be countersunk. Another

properly adjust a gun for any type of work.

hazard is the closeness of the rivet set to the metal

The rivet should be pushed into proper position and

during riveting. If considerable skill is not used, the

held there firmly, with the set of the rivet gun resting

rivet set will damage the metal. Flush rivets are made

squarely against the rivet head. The bucking bar is held

with heads of several different angles, but the

firmly and squarely against the protruding rivet shank.

100-degree rivet is standard for all Navy aircraft.

(In most instances, another person, called the "bucker"

The two methods used to countersink flush rivets

must manipulate the bucking bar.) The gunner then

are dimple and machine countersinking. In some

exerts pressure on the trigger and starts driving. The

instances, a combination of the two may be used; in

gun must be held tightly against the rivet head, and it

other words, the top sheet of an assembly may be

must not be removed until the trigger has been released.

dimpled while the under sheet is machine countersunk.

The bucker removes the bucking bar and checks the

upset head after the gunner has stopped driving. A

Rivet Driving

signal system is usually employed to develop the

necessary teamwork, and consists of tapping lightly

Before driving any rivets, make sure all the holes

against the work. One tap may mean, "not fully driven,

line up perfectly, all the shavings and burrs have been

hit it again"; two taps may mean "good rivet"; three taps

removed, and the parts to be riveted are fastened

may mean, "bad rivet, remove and drive another."

The upset head, often referred to as the bucktail,

should be 1 1/2 times the original diameter of the shank

in width and 1/2 times the original diameter in height,

as shown in figure 4-46. If the head formed is narrower

Figure 4-45.--Incorrect countersinking.

Figure 4-46.--Rivet dimensions before and after bucking.

4-25