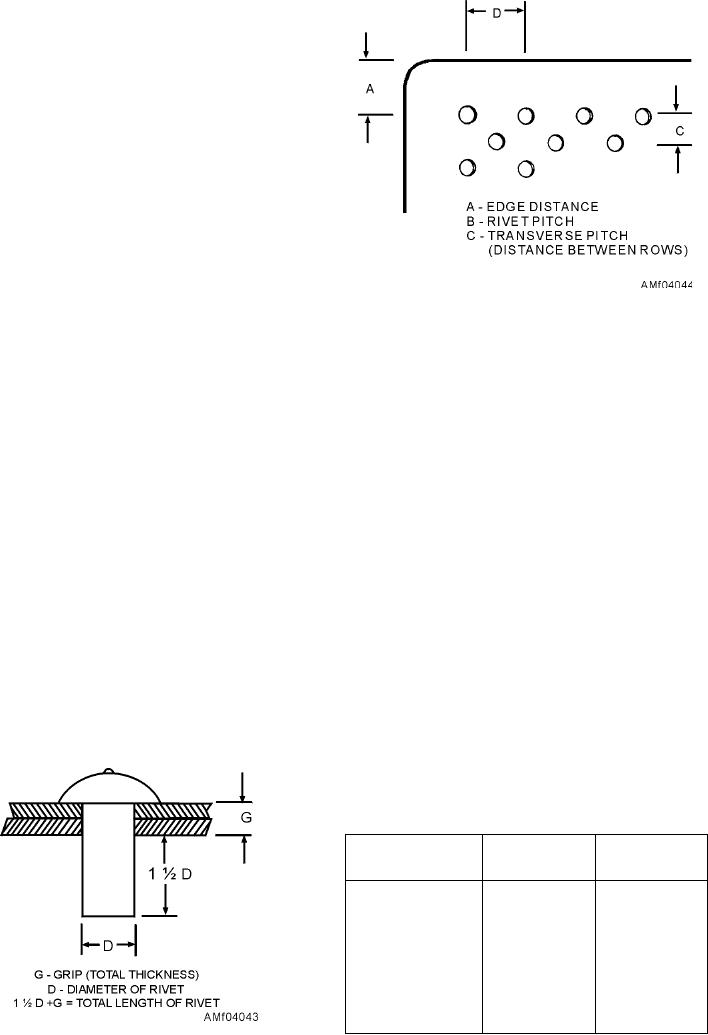

equal the sum of the thickness of the metal plus 1 1/2

times the diameter of the rivet, as shown in figure 4-43.

The formula for determining rivet length is as follows:

1 1/2 x D + G = L

Where:

D = the rivet diameter,

G = the grip (total thickness of material, and

L = the total length of the rivet.

Spacing and Edge Distance

Rivet spacing, also referred to as rivet pitch, is the

distance between the rivets in the same row, and is

measured from the rivet center to the rivet center.

Figure 4-44.--Rivet spacing and edge distance.

Transverse pitch is the distance between the rows of

rivets, and is measured from the rivet center to rivet

EDGE DISTANCE.--The edge distance for all

center. Edge distance is the distance from the center of

rivets, except those with a flush head, should not be less

the rivet to the edge of the material being riveted.

than twice the diameter of the rivet shank nor more than

four times the diameter of the rivet shank. Flush-head

There are no specific rules that apply to every case

rivets require an edge distance of at least 2 1/2 times the

or type of riveting. There are, however, certain general

diameter. If rivets are placed to close to the edge of the

rules that should be followed.

sheet, the sheet is apt to crack or pull away from the

RIVET SPACING.--Rivet spacing (pitch)

rivets. If they are placed too far away from the edge, the

depends upon several factors, principally the thickness

sheet is apt to turn up at the edge.

of the sheet, the diameter of the rivets, and the manner

NOTE: On most repairs, the general practice is to

in which the sheet will be stressed. Rivet spacing

use the same rivet spacing and edge distance that the

should never be less than three times the rivet diameter.

manufacturer used in the surrounding area, or the

Spacing is seldom less than four times the diameter nor

structural repair manual for the particular aircraft may

more than eight times the diameter.

be consulted. Figure 4-44 shows rivet spacing and edge

TRANSVERSE PITCH.--When two or more

distance.

rows of rivets are used in a repair job, the rivets should

be staggered to obtain maximum strength. The distance

Drilling Rivet Holes

between the rows of rivets is called "transverse pitch."

Standard twist drills are used to drill rivet holes.

Transverse pitch is normally 75 percent of existing rivet

Table 4-2 specifies the size drill to be used with the

pitch, but should never be less than 2 1/2 times the

various size rivets. Note that there is a slight clearance

diameter.

in each case. This prevents binding of the rivet in the

hole.

Table 4-2.--Drill Sizes for Various Size Rivets

Rivet Diameter

Drill No.

Drill Size

3/32

No. 41

0.0960

1/8

No. 30

.1285

5/32

No. 21

.1590

3/16

No. 11

.1910

1/4

No. F

.2570

5/16

No. P

.3230

3/8

No. W

.3860

Figure 4-43.--Rivet length.

4-24