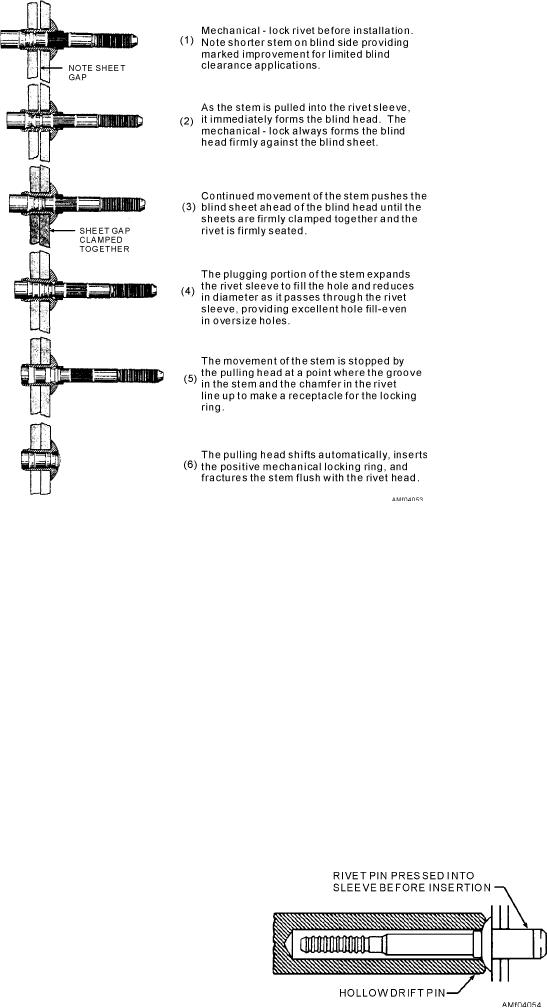

Figure 4-53.--Self-plugging rivet (mechanical lock).

Shank expansion through the action of the extruding

the installation, inspection, and removal procedures are

angle, blind head formation, and setting of the

basically the same.

mechanical lock in the rivet head all follow in sequence

Installation Procedures

and require but a fraction of a second.

In some places, such as near the trailing edge of a

Proper driving procedures are vital to obtain a firm

control surface, there may not be sufficient space

joint. The recommended procedures are as follows:

between the two surfaces to insert the rivet. In such

1. Hold the head of the gun steady and at right

cases, the pin may be forced into the hollow shank until

angles to the work.

the head of the pin touches the end of the shank. Since

no further shank expansion will result, the drill hole

2. Press on the head of the gun hard enough to

should not be enlarged to provide a free fit of the

hold the rivet firmly against the work. Do not use a great

already expanded rivet. To insert the rivet, you should

amount of pressure unless it is necessary to bring the

use a hollow drift pin that will accommodate the rivet

part being riveted into contact.

pin and the locking collar. See figure 4-54. This allows

3. Squeeze the gun trigger and hold it until the

a driving force to be exerted on the head of the rivet.

rivet pin breaks, and then release the trigger. The next

Drive the head into firm contact with the sheet, and then

rivet should not be driven until the return action has

caused the gun to latch. A distinct click will be heard.

The click indicates the gun is ready for the next

installation cycle.

Figure 4-53 shows the complete installation of a

self-plugging (mechanical lock) rivet.

The rivet is actually cold squeezed by the action of

the pinhead drawing against the hollow shank end.

Figure 4-54.--Inserting self-plugging rivet (mechanical lock).

4-29