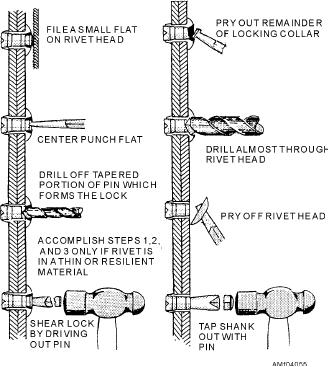

prohibits this, partially remove the rivet head by filing

apply the rivet pull tool in the usual manner to upset the

or with a rivet shaver. An alternative would be to file the

rivet.

pin flat, center punch the flat, and carefully drill out the

Because of the mechanical lock feature of the pin

tapered part of the pin forming the lock.

and sleeve, the driven rivet is substantially the

2. Pry the remainder of the locking collar out with

mechanical equivalent of a one-piece solid rivet.

a drift pin.

Inspection

3. Use the proper size drill to drill almost

completely through the rivet head. For a

Visual inspection of the seating of the pin in the

1/8-inch-diameter rivet, use a No. 31 drill; for a 5/32,

manufactured head is the most reliable means of

use a No. 24; and for a 3/16, use a No. 15.

inspection. If the proper grip length has been used and

the locking collar and broken end of the pin are

4. Break off the drilled head with a drift pin.

approximately flush with the manufactured head, the

5. Drive out the remainder of the rivet with a pin

rivet has been properly upset and the lock formed.

that has a diameter equal to or slightly less than the rivet

Insufficient grip length is indicated by the pin breaking

diameter.

below the surface of the manufactured head. Excessive

Q4-18.

What is the most commonly used layout fluid?

grip length is indicated by the pin breaking off well

above the manufactured head. In either case, the

Q4-19.

What is the only thing you should use a

locking collar might not be properly seated and an

scriber for when laying out aluminum or

unsatisfactory lock would be formed.

magnesium?

Q4-20.

The amount of material consumed in the

Removal

bending process is known by what term?

Removal of this rivet can be accomplished easily

Q4-21.

What is the outside dimension of the formed

and without damage to the work if you use the

part called?

following procedures. See figure 4-55.

Q4-22.

The setback is the combination of the metal

1. Shear the lock by driving out the pin with a

thickness and what other factor?

tapered steel drift pin not over 3/32-inch diameter at the

Q4-23.

Machines used to cut sheet metal are

small end. If you are working on thin material, back up

classified into what two groups?

the material while driving out the pin. If inaccessibility

Q4-24.

When using a vise and forming blocks to

manually form a part, what are the three

materials that the mallet you use must be

made from?

Q4-25.

When you cut sheet metal, how much should

you add to allow for trim?

Q4-26.

Before making any bends on the layout, what

should you do to make sure the brake settings

are right?

Q4-27.

How many adjustments must be checked on

the bar folder before you can properly bend

and fold metal?

Q4-28.

To form cylindrical or conical shapes, you

should use what machine?

Q4-29.

What machine should you use to make a

groove on a bucket?

Q4-30.

What determines the minimum rivet

Figure 4-55.--Removing self-plugging rivets (mechanical

diameter?

lock).

4-30