A layout fluid should be applied to the surface of

the metal so that the pattern will stand out clearly. Any

one of several approved fluids may be used. Bluing

fluid, a blue dye dissolved in alcohol, is the most

commonly used layout fluid. Since it does not protect

metal against corrosion or serve as a paint binder,

bluing fluid should be removed after use. Either

ordinary paint thinner or alcohol may be used to remove

it.

To begin the layout, you should ensure that one

edge of the metal is straight. All measurements can then

be based on the straight edge of the sheet. Lines at a

known angle or parallel to the straight edge can be

made by marking points from a combination square

held firmly against the straight edge.

If it is impossible to obtain a straight edge on a

sheet to start a layout or if the distance from the edge is

too great, a reference line may be used. The reference

line may be made by connecting any two points with a

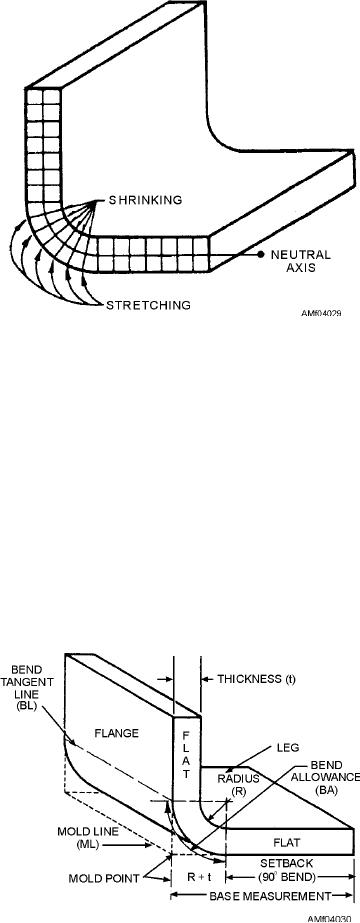

Figure 4-29.--Neutral axis.

straight line. Perpendiculars may be erected to the

reference line by using a compass or dividers. Once the

BEND ALLOWANCE TERMS

perpendicular is accurately established, it may be used

as a basis for almost any layout.

You should be familiar with the following terms

A scriber must never be used for drawing lines on

related to a bending job. Figure 4-30 shows the meaning

aluminum or magnesium except to indicate where the

of some of these terms.

metal is to be cut or drilled. All other lines should be

Bend allowance. The amount of material

drawn with a soft-lead pencil. The pencil mark should

consumed in making a bend.

be removed from aluminum and magnesium to prevent

an electrolytic action that will eventually cause

Closed angle. An angle that is less than 90

corrosion. It can be removed with isopropyl alcohol or

degrees when measured between legs. When the

MEK. If you fold a piece of metal along a sharp line

made with a scriber, the scribed line will weaken the

metal and possibly cause it to crack along the bend. If it

does not crack at the time of bending, it is very

susceptible to cracking at a later time when failure of

the part could be dangerous.

Bend Allowance

When you are bending metal to exact dimensions,

the amount of material needed to form the bend must be

known. The term for the amount of material that is

actually used in making the bend is bend allowance.

Bending compresses the metal on the inside of the

bend and stretches the metal on the outside of the bend.

Approximately halfway between these two extremes

lies a space that neither shrinks nor stretches. This

space is known as the neutral line or neutral axis. Figure

4-29 shows the neutral axis of a bend. It is along this

Figure 4-30.--Bend allowance terms.

neutral axis that bend allowance is computed.

4-16