damage them. Never use brakes for bending metal that

is beyond the machine's capacity with respect to

thickness, shape, or type. Never try to bend rod, wire,

strap iron, or spring steel sheets in a brake. If it is

necessary to hammer the work, take it out of the brake

first.

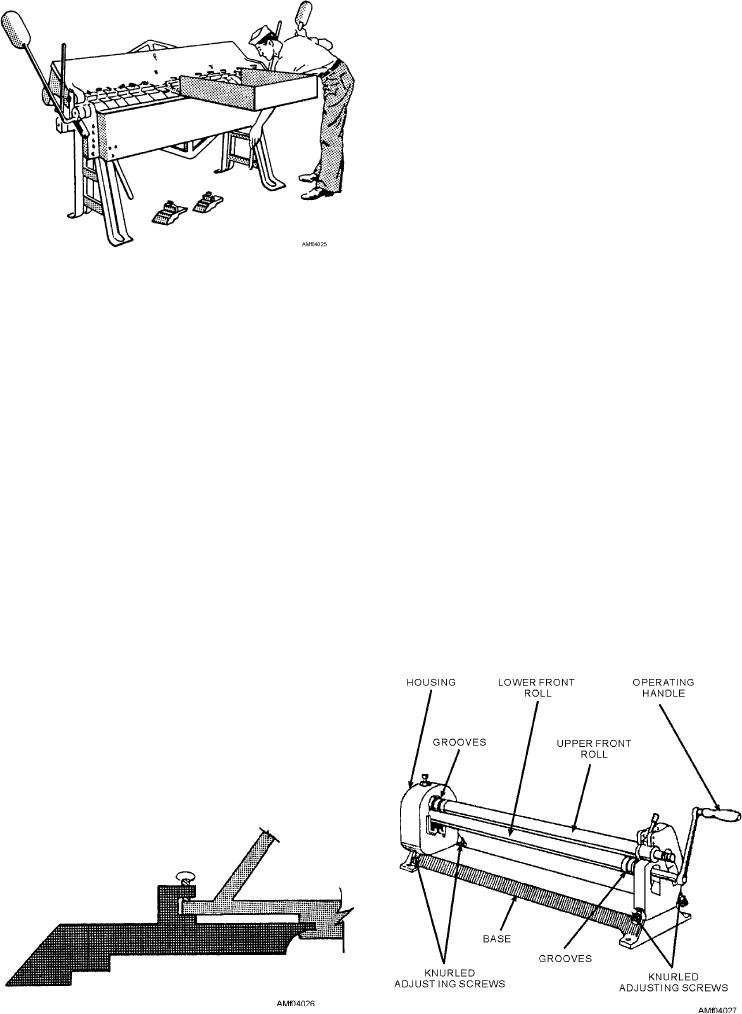

FORMING MACHINES.--A sheet metal object

made on a brake will have corners (bends) and sides

(flanges). On a forming machine, it is possible to make

an object without sides. For example, you can make a

circular object such as a funnel. The forming machines

used in the Navy are usually located at aircraft

intermediate maintenance departments (AIMDs). The

Figure 4-25.--Box and pan brake being used to form box.

two most common machines are the slip roll and the

rotary.

BOX AND PAN BRAKE.--The box and pan

Slip-Roll Forming Machine.--Sheet metal can be

brake, shown in figure 4-25, is often called the "finger

formed into curved shapes over a pipe or a mandrel, but

brake" because it does not have a solid upper jaw as

the slip-roll forming machine is easier to use and

does the cornice brake. Instead, it is equipped with a

produces more accurate bends. Rolling machines are

series of steel fingers of varying widths. The finger

available in various sizes and capacities. Some are hand

brake can be used to do everything that the cornice

operated, like the one shown in figure 4-27, and others

brake can do and several things that the cornice brake

are power operated.

cannot do.

The machine shown in the illustration has two rolls

The finger brake is used to form boxes, pans, and

in the front and one roll at the rear. You can adjust

other similarly shaped objects. If these shapes were

screws on each end of the machine to control the

formed on a cornice brake, you would have to

distance between the front rolls. By varying the

straighten part of the bend on one side of the box in

adjustments, the machine can be used to form

order to make the last bend. With a finger brake, you

cylinders, cones, and other curved shapes. The front

simply remove the fingers that are in the way and use

rolls grip the metal and pull it into the machine;

only the fingers required to make the bend.

therefore, the adjustment of distance between the two

The fingers are secured to the upper leaf by

front rolls is made on the basis of the thickness of the

thumbscrews, as shown in figure 4-26. All the fingers

sheet being worked.

that are not removed for an operation must be securely

seated and firmly tightened before the brake is used.

To keep brakes in good condition, you should keep

the working parts well oiled and be sure the jaws are

free of rust and dirt. When you operate brakes, be

careful to avoid doing anything that would spring the

parts, force them out of alignment, or otherwise

Figure 4-26.--Finger secured in box and pan brake.

Figure 4-27.--Slip-roll forming machine.

4-14