metals, faster output, and more professional results,

BEND ALLOWANCE FORMULA

machines designed for metal-cutting purposes are used.

By experimentation with actual bends in metals,

Machines used to cut sheet metal may be divided

aircraft engineers have found that accurate bending

into two groups--manually operated and power

results could be obtained by using the following

operated. Each cutting machine has a definite cutting

formula for any degree of bend from 1 to 180:

capacity that should never be exceeded. A few of the

(0.0173 x R + 0.0078 x T) x N = BA

more common types that may be available to you have

been described in the previous sections.

Where

R = the desired bend radius,

BENDING SHEET METAL

T = the thickness of the material, and

Straight-line bends and folds in sheet metal are

N = the number of degrees of bend.

ordinarily made on the cornice brake and bar folder;

however, a considerable amount of bending is also

Refer to the NA 01-1A-1 for the appropriate bend

completed by hand-forming methods. Hand forming

allowance tables.

may be accomplished by using stakes, blocks of wood,

angle iron, a vise, or the edge of a bench.

CUTTING SHEET METAL

Bending Over Stakes

Once a project has been laid out on the metal, the

next step is to cut it to shape. The type of cutting

Stakes are used to back up sheet metal to form

equipment to be used depends primarily upon the type

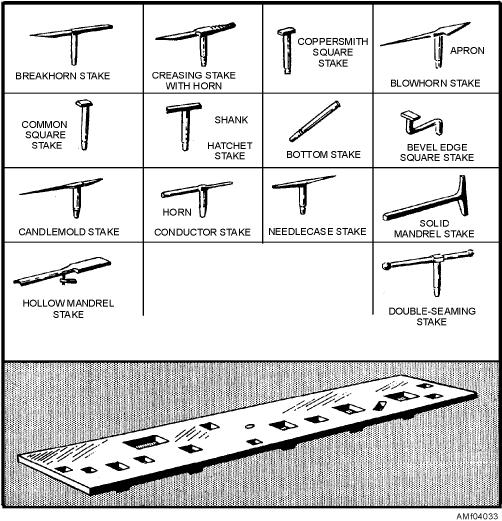

many different curves, angles, and seams. Stakes are

and thickness of the material. Another consideration is

available in a wide variety of shapes, some of which are

the size and number of pieces to be cut. A few relatively

shown in figure 4-33. The stakes are held securely in a

thin pieces of comparatively soft metal may be cut

stake holder or stake plate, which is anchored in a

faster with hand-trimming methods. But for harder

Figure 4-33.--Stakes and stake plates.

4-18