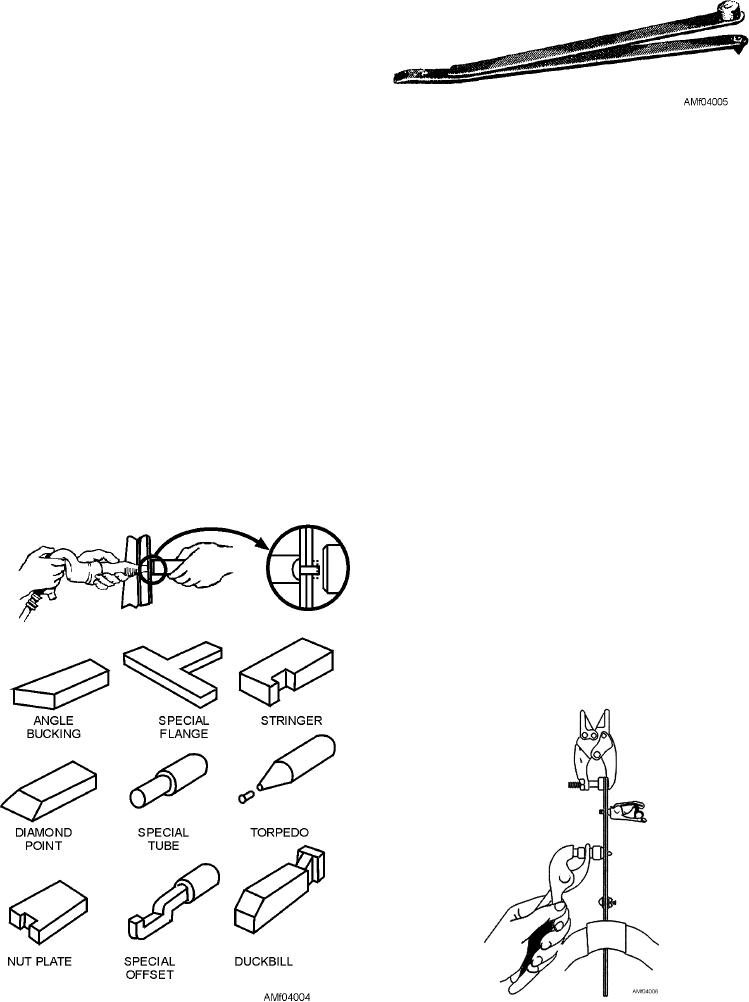

Bucking Bars

Bucking bars are tools used to form bucktails (the

head formed during riveting operations) on rivets. They

come in many different shapes and sizes, as shown in

figure 4-4. Bucking bars are normally made from an

alloy steel similar to tool steel. The particular shape to

be used depends upon the location and accessibility of

Figure 4-5.--Hole finder.

the rivet to be driven. The size and weight of the bar

but firmly against the end of the rivet shank so as not to

depend on the size and alloy of the rivet to be driven.

unseat the rivet head. The inertia of this tool provides

Under certain circumstances, and for specific rivet

the force that bucks (upsets) the rivet and forms a flat,

installations, specially designed bucking bars are

head like bucktail.

manufactured locally. These bars are normally made

from tool steel. The portion of the bar designed to come

Hole Finder

in contact with the rivet has a polished finish. This helps

to prevent marring of formed bucktails. Bucking-bar

A hole finder is a tool used to transfer existing holes

faces must be kept smooth and perfectly flat and the

in aircraft structures or skin to replacement skin or

edges and corners rounded.

patches. See figure 4-5. The tool has two leaves parallel

NOTE: Never hold a bucking bar in a vise unless

to each other and fastened together at one end. The

the vise jaws are equipped with protective covers to

bottom leaf of the hole finder has a teat installed near

prevent marring of the bucking bar.

the end of the leaf that is aligned with a bushing on the

top leaf. The desired hole to be transferred is located by

A satisfactory rivet installation depends largely on

fitting the teat on the bottom leaf of the hole finder into

the condition of the bucking bar and your ability to use

the existing rivet hole. Drilling through the bushing on

it. If possible, hold the bucking bar in such a manner

the top leaf makes the hole in the new part. If the hole

that will allow the longest portion of the bar to be in line

finder is properly made, holes drilled in this manner

with the rivet. You should hold the bucking bar lightly

will be perfectly aligned. A separate duplicator must be

provided for each diameter of rivet to be used.

Skin Fasteners

There are several types of skin fasteners used to

temporarily secure parts in position for drilling and

riveting and to prevent slipping and creeping of the

parts. C-clamps, machine screws, and Cleco fasteners

are frequently used for this purpose. See figure 4-6.

Figure 4-6.--Skin fasteners.

Figure 4-4.--Bucking bars.

4-3