After the completion of the proof pressure test,

drain the hose assembly and clean. Install the protective

closures. Install the identification tag. Prepare the hose

assembly for installation or storage.

TEST STANDS

All flexible hose manufactured in the shop must be

hydraulic or pneumatic pressure tested prior to

installation in the aircraft. Two types of hose burst test

stands, Greer and CGS Scientific, are typical of those

used for this purpose.

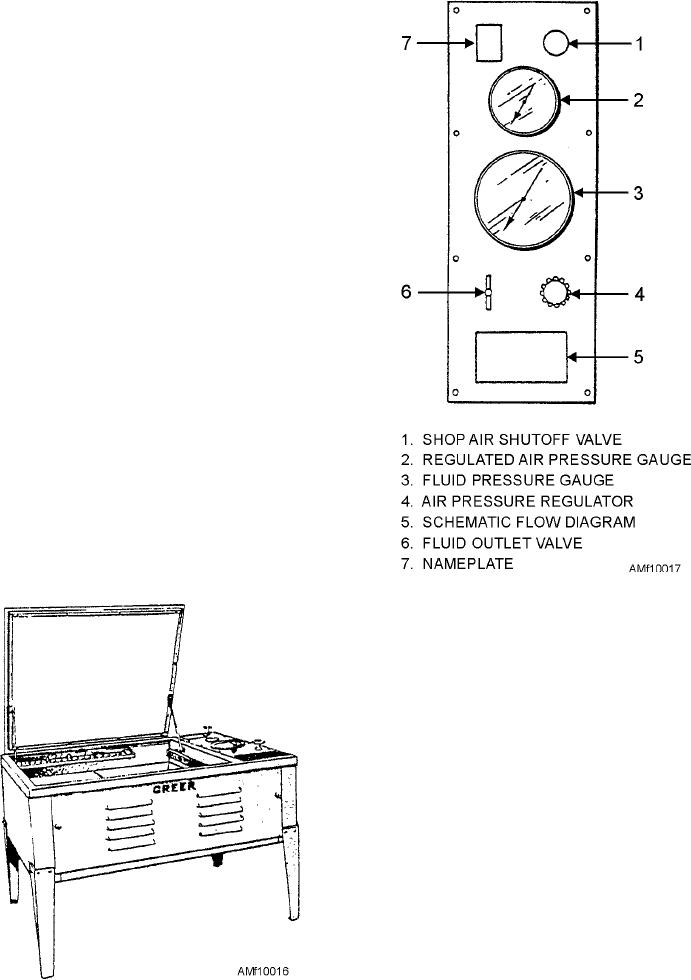

Aircraft Hydraulic Hose Test Stand (Greer)

The hose test stand shown in figure 10-16 is

manufactured by Greer Hydraulics, Incorporated. This

test stand is designed especially for proof pressure

testing aircraft hose assemblies and is capable of

developing static pressures up to 30,000 psi.

The high static pressures required for proof testing

are produced by a booster pump powered by shop air

having a pressure of 80 to 120 psi. The unit is mounted

on four legs, which provide mounting holes for bolting

it to the deck. Figure 10-17 shows the instruments and

controls, and table 10-5 lists the functions of each. You

should be familiar with these instruments and controls

before using the test stand. To operate the aircraft

hydraulic hose test stand (Greer), follow the procedures

described below.

Figure 10-17.--Instruments and controls.

Before you operate the test stand, make the

following checks and adjustments: Make sure that the

reservoir is filled. Connect the shop air supply line to

the stand and open the air shutoff valve. Turn the

pressure regulator to the low-pressure position. There

are no special starting instructions since the stand starts

to operate as soon as air pressure is admitted into the

circuit by opening the air shutoff valve. The stand may

be warmed up by capping all pressure outlet ports,

opening the fluid outlet valve, and allowing the pump to

operate for 1 minute.

INSTALLING HOSE LINES FOR TEST.--

With the air pressure regulator set at zero, lift the cover

to the open position. Select the proper size adapter

(with O-ring) to fit the hose line to be tested, and install

it in the pressure manifold outlet port. Connect one end

of the test hose line to the manifold adapter. Plug the

manifold ports not being used. Connect the bleed valve

Figure 10-16.--Aircraft hose burst test stand (Greer).

to the adapter. Connect a second adapter on the other

10-14