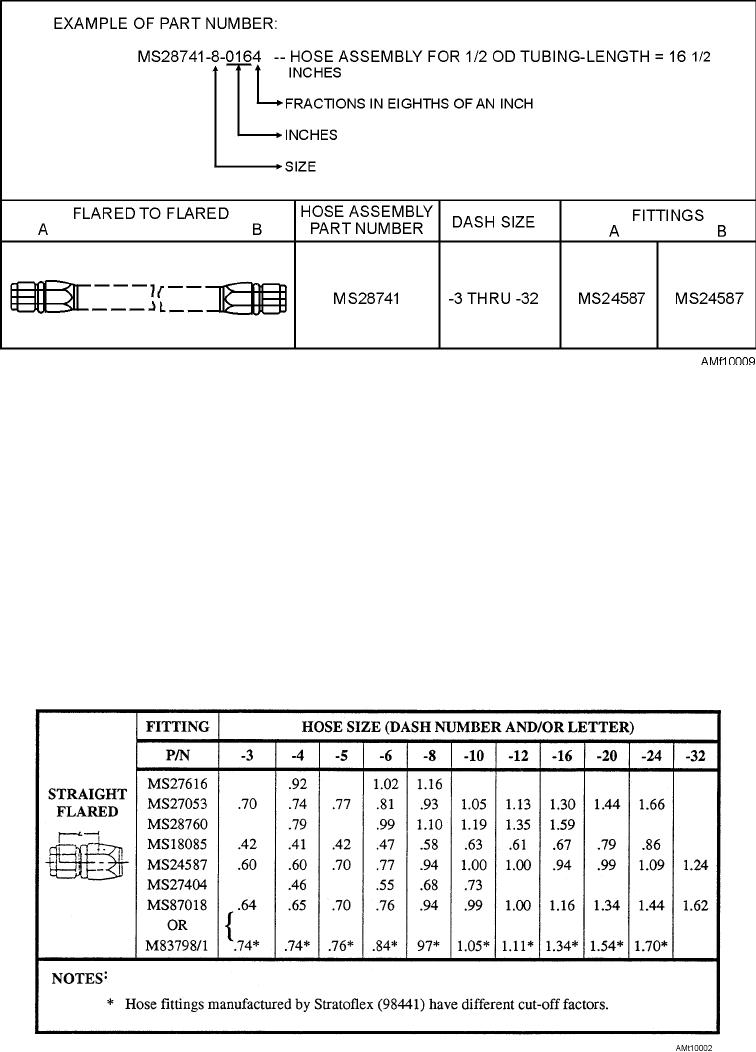

Figure 10-9.--Synthetic rubber medium-pressure hose assembly.

depot organization levels. Undamaged end fittings on

Procedures

the old length of hose may be removed and reused;

When failure occurs in a flexible hose equipped

otherwise, new fittings must be drawn from supply

with swaged end fittings, the unit is generally replaced

along with a sufficient length of hose.

without attempting a repair. The correct length of hose,

The following assembly procedures are for

complete with factory-installed end fittings, is drawn

instructional purposes only. When fabricating hose

from supply.

assemblies, refer to the Aviation Hose and Tube

When failures occur in hose assemblies equipped

Manual, NAVAIR 01-1A-20. Hose assembly part

with reusable style end fittings, the fabrication of the

number MS 28741-80164 (fig. 10-9), per MIL-H-8795,

replacement unit is the function of the intermediate and

is used here as an example of fabrication procedures.

Table 10-2.--Hose Cutoff Factor (In Inches)

10-10