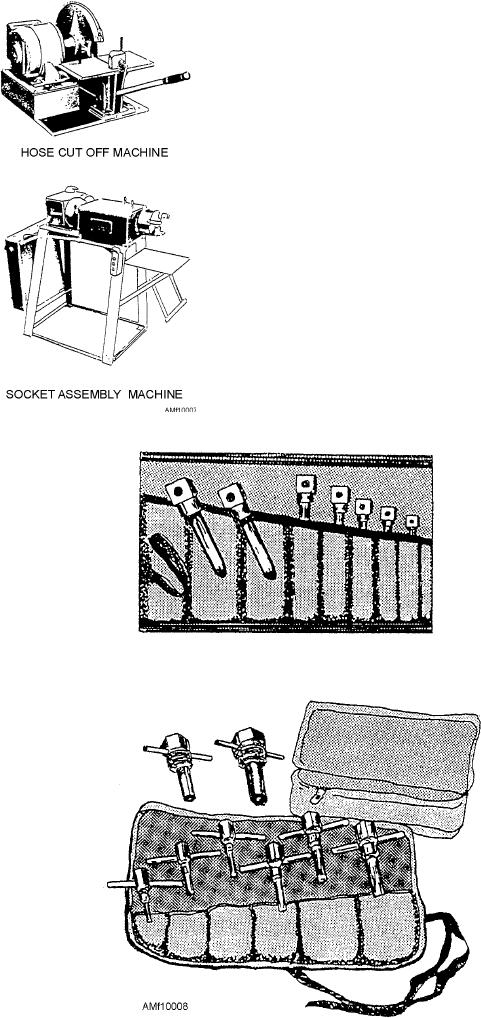

Equipment and Tools

Fabricating hose assemblies is a function of

intermediate- and depot-level maintenance. The

intermediate and depot shops are equipped with hose

fabricating machines (fig. 10-7) and proof-test

equipment. Each machine or equipment is supplied

with operating instructions.

The basic hand tools that are required to fabricate

hose assemblies up to 3,000 psi operating pressure are a

bench vise, a hose cutoff machine, open end wrench

sets, a sharp knife, slip joint pliers, an oil can for

lubricating oil, a marking pencil, a small paint brush,

masking or plastic electrical tape, a steel ruler, a

thickness gauge (leaf type), and a protractor.

Mandrels are special hand tools (fig. 10-8) that are

not required but are recommended for fabricating hose

assemblies. During hose assembly fabrication,

mandrels can be used to protect sealing surfaces,

support inner tubes, and guide fitting nipples into

hoses.

Figure 10-7.--Hose fabricating machines.

Figure 10-8.--Mandrel kits.

10-9