struts. The amount a strut is inflated depends upon the

5. When the strut is fully compressed, the air

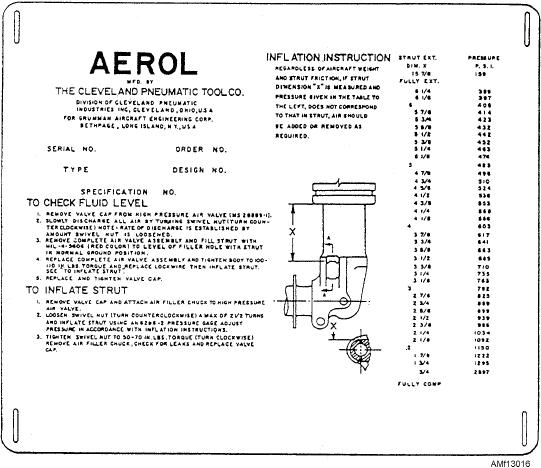

specific aircraft strut being serviced. One manufacturer

valve assembly may be removed by breaking the safety

may use a strut inflation chart, such as the one shown in

wire and turning the 3/4-inch body nut counter-

view D of figure 13-15. The strut is measured as

clockwise.

indicated at dimension "A." This measurement, in

6. Use the type of hydraulic fluid specified on the

inches, is then located on the bottom of the inflation

shock strut inspection plate to fill the strut to the level of

chart. For example, locate the measurement of 1.75

the air valve opening. Figure 13-16 shows the

inches on the chart. From this point, vertically trace an

instruction plate found on one type of aircraft main

imaginary line until it intersects the curved line. At this

landing gear strut. Improper oil level in the strut

point of intersection, horizontally trace a second

chamber will decrease the shock absorbing capabilities

imaginary line to the left edge of the chart. The figure

of the strut and could cause the strut to bottom out

indicated at this point (550 psi) is the required pressure

during landing. This would damage the strut and/or

for that particular extension of the strut.

wing structure.

All aircraft struts are not measured from the same

NOTE: The instruction plate may be found on the

points. View E of figure 13-15 shows another location

strut or on the wheel door near the strut.

where strut extension is measured. The proper

7. Reinstall the air valve assembly, using a new

procedure to use will always be found on the instruction

O-ring packing. Torque the air valve body hex nut from

plate attached to the shock strut. If these instructions

100 inch-pounds to 110 inch-pounds, as shown in view

are not legible, consult the applicable MIM.

B of figure 13-15.

If the strut's chamber is underpressurized, the strut

8. Lockwire the air valve assembly to the strut,

may not overcome normal O-ring friction during

using the holes provided in the body nut.

extension on takeoff. This condition could prevent the

strut from fully extending, thus the torque scissors limit

9. I n f l a t e t h e s t r u t , u s i n g a r e g u l a t e d

switch would not actuate to close the electrical circuit

high-pressure source of nitrogen or dry air. Under no

to retract the gear. It would also cause the strut to

circumstances should any type of bottle gas other than

bottom during taxiing and landing operations.

nitrogen or compressed air be used to inflate shock

Figure 13-16.--Landing gear strut servicing instruction plate.

13-16