doors, hydraulic lines, and electrical connections.

Lubricate all reinstalled linkages, and check the landing

gear for proper operation.

SERVICING, BLEEDING, AND INSPECTING

SHOCK STRUTS

For efficient operation of shock struts, the proper

fluid level and pneumatic pressure must be maintained.

Before you check the fluid level, you should consult the

aircraft MIM. Deflating a strut can be a dangerous

operation unless the servicing personnel are thoroughly

familiar with high-pressure air valves and observe all

the necessary safety precautions.

Servicing

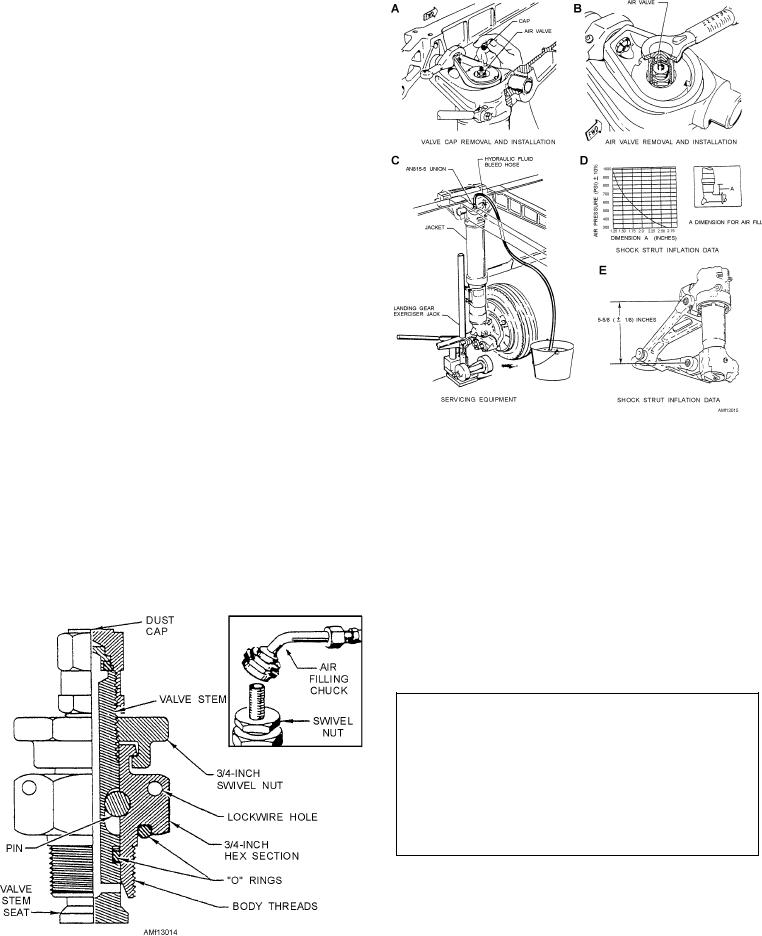

The high-pressure air valve shown in figure 13-14

is used on most naval aircraft. This air valve is used on

struts, accumulators, and various other components that

must be serviced with high-pressure air or nitrogen.

The following procedures for deflating a typical

shock strut, servicing with hydraulic fluid, and

reinflating is for instructional purposes only. See figure

13-15. For specific aircraft, consult the appropriate

Figure 13-15.--Servicing a landing gear strut.

aircraft MIM.

1. Position the aircraft so that the shock struts are

NOTE: Some aircraft must be placed on jacks with

in the normal ground operating position. Ensure that

their struts completely extended for servicing.

personnel, workstands, and other obstacles are clear of

2. Remove the cap from the air valve, as shown in

the aircraft.

view A of figure 13-15.

3. Release the air pressure in the strut by slowly

turning the air valve swivel nut counterclockwise

approximately 2 turns. This action can normally be

accomplished with the use of a combination wrench.

WARNING

When loosening the swivel nut, ensure that the

3/4-inch hex body nut is either lockwired in place or

held tightly with a wrench. If the swivel nut is

loosened before the air pressure has been released,

serious injury may result to personnel.

4. Ensure that the shock strut compresses as the

air or nitrogen pressure is released. In some cases, it

may be necessary to rock the aircraft after deflating to

ensure complete compressing of the strut.

Figure 13-14.--High-pressure air valve, type MS 28889.

13-15