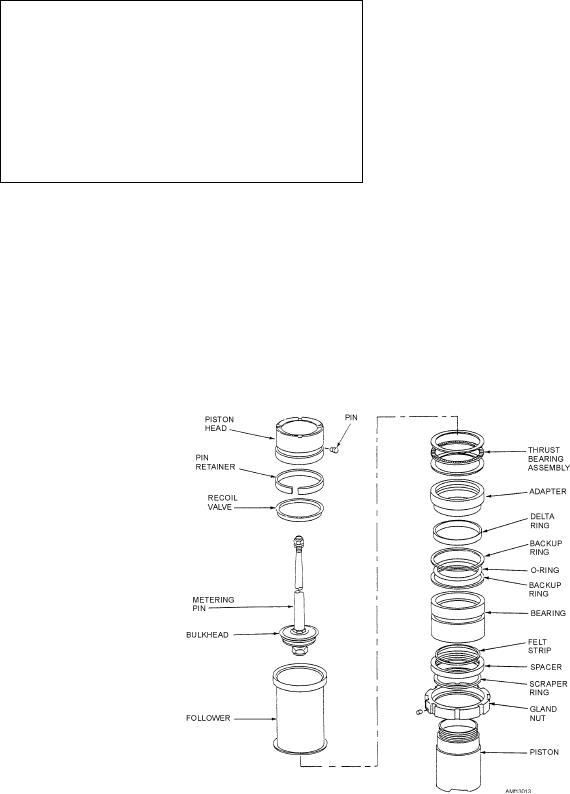

LOWER STRUT AND GLAND SEAL

the sequence that require quality assurance verification

REPLACEMENT

before proceeding to the next step. Landing gear doors

may have to be deactivated or disconnected to check for

On most aircraft the piston O-rings and delta rings

proper up lock actuation and gear up clearances.

can be replaced at the organizational level of

Complete alignment includes down-and-locked

maintenance while the strut is installed on the aircraft.

adjustment, up-and-locked adjustment, and proper door

Procedures for replacing the seals in a main gear recoil

operation. Verification of the emergency landing gear

strut at the organizational level of maintenance consist

system operation is normally required in verifying the

of jacking the aircraft in accordance with the applicable

landing gear system. Some MIMs cover the emergency

MIM. Remove the wheel and brake assemblies so that

system as a separate procedure, but a complete

handling of the lower strut is easier. Remove the cap

operational checkout should include the emergency

from the strut filler valve and release the nitrogen

backup system.

pressure from the strut by opening the valve swivel nut

counterclockwise. Remove the necessary wire bundles,

hydraulic lines, etc., that form a connection between the

WARNING

upper cylinder and lower piston of the strut. Remove

Ensure that all personnel involved in landing gear

the up and down lines from the gear actuating cylinder.

maintenance are clear of the landing gear and doors

Connect a hand pump or check and fill stand lines so

and that signals between the person in the cockpit and

that the strut may be retracted to an angle that will allow

the crew leader are clearly understood before raising

the piston to be withdrawn from the cylinder. Cap any

or lowering the landing gear. Failure to do so could

loose lines or fittings to prevent contamination. On

result in personnel injury.

some aircraft, you will have to use a spring compressor

or some other means to release tension on the gear

down lock mechanism so that the gear can be partially

RECOIL STRUT MAINTENANCE

retracted.

According to current maintenance directives,

With the strut cylinder secured in the partially

maintenance of recoil struts (including minor repair

retracted position and all pressure released from the

and miscellaneous parts replacement) should be

strut, the upper and lower torque arms can be

confined to work that can be performed with only

disconnected. Cut the lockwire and remove the lock

partial disassembly of the equipment. Instructions for

screws from the gland nut. Figure 13-13 shows a main

major or complete overhaul are covered in overhaul

gear recoil strut piston. Refer to figure 13-13 while you

instructions manuals for recoil struts, and such work is

read the following seal replacement material.

performed by specialized shops.

Figure 13-13.--Main gear recoil strut piston.

13-13