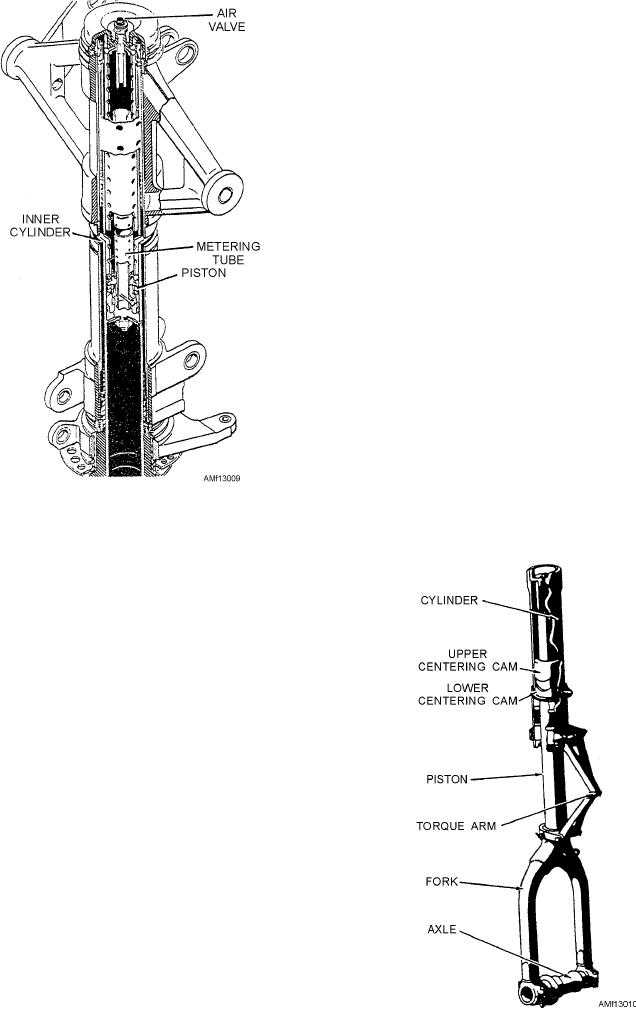

Nose gear shock struts are provided with an upper

centering cam that is attached to the upper cylinder and

a mating lower centering cam that is attached to the

lower cylinder. See figure 13-10. These cams serve to

line up the wheel and axle assembly in the

straight-ahead position when the shock strut is fully

extended. This prevents the nosewheel from being

cocked to one side when the nose gear is retracted,

preventing possible structural damage to the aircraft.

These mating cams also keep the nosewheel in a

straight-ahead position prior to landing when the strut

is fully extended.

Nose and main gear shock struts are usually

provided with jacking points and towing lugs. Jacks

should always be placed under the prescribed points.

When towing lugs are provided, the towing bar should

be attached only to these lugs.

All shock struts are provided with an instruction

plate that gives, in a condensed form, instructions

relative to the filling of the strut with fluid and inflation

of the strut. The instruction plate also specifies the

correct type of hydraulic fluid to use in the strut. The

plate is attached near the high-pressure air valve. It is of

the utmost importance that you always consult the

Figure 13-9.--Landing gear shock strut (metering tube type).

applicable aircraft MIMs and familiarize yourself with

the instructions on the plate prior to servicing a shock

stroke and to prevent a too rapid extension of the shock

strut with hydraulic fluid and nitrogen or air.

strut, which would result in a sharp impact at the end of

the stroke.

The majority of shock struts are equipped with an

axle that is attached to the lower cylinder to provide for

tire and wheel installation. Shock struts not equipped

with axles have provisions on the end of the lower

cylinder for ready installation of the axle assembly.

Suitable connections are also provided on all shock

struts to permit attachment to the aircraft.

A fitting, which consists of a fluid filler inlet and a

high-pressure air valve, is located near the upper end of

each shock strut to provide a means of filling the strut

with hydraulic fluid and inflating it with air or nitrogen.

A packing gland designed to seal the sliding joint

between the upper and lower telescoping cylinders is

installed in the open end of the outer cylinder. A

packing gland wiper ring is also installed in a groove in

the lower bearing or gland nut on most shock struts to

keep the sliding surface of the piston or inner cylinder

free from dirt, mud, ice, and snow. Entry of foreign

matter into the packing gland will result in leaks. The

majority of shock struts are equipped with torque arms

attached to the upper and lower cylinders to maintain

correct alignment of the wheel.

Figure 13-10.--Nose gear shock strut.

13-9