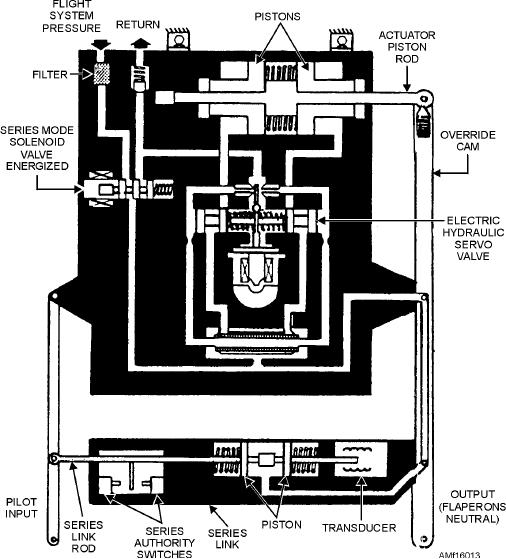

Figure 16-13.--Flaperon autopilot actuator.

series-link cylinder acts as a rigid link that transfers

SYSTEM ACTUATORS.--The flaperon system

input lever motion to the output lever.

actuators directly control the flaperon movement in

response to mechanical movement from the autopilot

In series mode, the solenoid valve energizes and

actuator. The actuator (fig. 16-12) consists of two

ports pressure to the servo valve. Pressure from the

tandem-mounted power pistons and a power valve

servo valve drives the actuator pistons together. This

shuttle. Mechanical inputs are introduced through the

pressure causes the pistons and the rod to act as one

load-relief (safety) bungee and the valve input lever to

piece. When the servo valve is at null, pressures in the

the power valve shuttle portion of the actuator. The

piston end chambers are equal. Electrical signals from

inputs cause a valve error and the porting of hydraulic

the automatic flight control system cause the

pressure to the power pistons. As the flaperon moves,

electrohydraulic servo valve to differ the pressures in

mechanical linkage attached to the actuator tends to

the end chambers. The signal provides the working

null this valve error. The power valve shuttle returns to

force for the actuator. The actuator piston rod drives

neutral. The flaperons remain in the selected position

the output lever. Pressure at the series link compresses

until new mechanical inputs are received from the pilot

a lock spring, unlocking the series link. The actuator

or the AFCS.

can stroke the pilot-commanded piston. When the pilot

moves the input link, relative motion between input

Combination Aileron/Spoiler Deflector System

and output causes the transducer to send a signal to the

AFCS amplifier. The signal combines with other flight

Navy aircraft employ more than one system for

stability signals, and the resultant signal operates the

lateral control of the aircraft. Figure 16-14 shows an

servo valve. The AFCS can be overridden by the pilot

aileron and spoiler/deflector arrangement to achieve

an increased roll rate about the longitudinal axis.

applying a stick force of 25 pounds.

16-13