wood were developed and used on later aircraft.

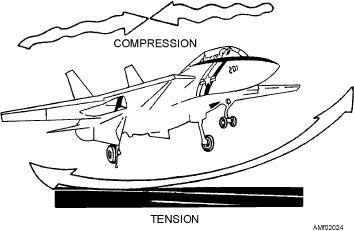

When an aircraft is on the ground, there is a

Materials currently used in aircraft construction may be

bending force on the fuselage. This force occurs

classified as either metallic or nonmetallic.

because of the weight of the aircraft itself. Bending

greatly increases when the aircraft makes a carrier

METALLIC MATERIALS

landing. This bending action creates a tension stress on

the lower skin of the fuselage and a compression stress

The most common metals in aircraft construction

on the top skin. This bending action is shown in figure

are aluminum, magnesium, titanium, steel, and their

2-24. These stresses are also transmitted to the fuselage

alloys. Aluminum alloy is widely used in modern

when the aircraft is in flight. Bending occurs due to the

aircraft construction. It is vital to the aviation industry

reaction of the airflow against the wings and

because the alloy has a high strength-to-weight ratio.

empennage. When the aircraft is in flight, lift forces act

Aluminum alloys are corrosion-resistant and

upward against the wings, tending to bend them

comparatively easy to fabricate. The outstanding

upward. The wings are prevented from folding over the

characteristic of aluminum is its lightweight.

fuselage by the resisting strength of the wing structure.

This bending action creates a tension stress on the

Magnesium, the world's lightest structural metal, is

bottom of the wings and a compression stress on the top

a silvery-white material weighing only two-thirds as

of the wings.

much as aluminum. Magnesium is used in the manu-

facture of helicopters. Magnesium's low resistance to

Q2-20.

What type of stress is produced by two forces

corrosion has limited its use in conventional aircraft.

pulling in opposite directions along the same

straight line?

Titanium

is

a

lightweight,

strong,

corrosion-resistant metal. It was discovered years ago,

Q2-21.

What force is the opposite of tension?

but only recently has it been made suitable for use in

Q2-22.

What type of stress is a combination of ten-

aircraft. Recent developments make titanium ideal for

sion and compression?

applications where aluminum alloys are too weak and

stainless steel is too heavy. In addition, titanium is

Q2-23.

What type of stress is the result of a twisting

unaffected by long exposure to seawater and marine

force?

atmosphere.

An alloy is composed of two or more metals. The

MATERIALS OF CONSTRUCTION

metal present in the alloy in the largest portion is called

LEARNING OBJECTIVES: Identify the

the base metal. All other metals added to the alloy are

various types of metallic and nonmetallic

called alloying elements. Alloying elements, in either

materials used in aircraft construction.

small or large amounts, may result in a marked change

An aircraft requires materials that must be both

in the properties of the base metal. For example, pure

light and strong. Early aircraft were made of wood.

aluminum is relatively soft and weak. When small

Lightweight metal alloys with a strength greater than

amounts of other elements such as copper, manganese,

and magnesium are added, aluminum's strength is

increased many times. An increase or a decrease in an

alloy's strength and hardness may be achieved through

heat treatment of the alloy. Alloys are of great im-

portance to the aircraft industry. Alloys provide materi-

als with properties not possessed by a pure metal alone.

Alloy steels that are of much greater strength than

those found in other fields of engineering have been

developed. These steels contain small percentages

of carbon, nickel, chromium, vanadium, and

molybdenum. High-tensile steels will stand stresses of

50 to 150 tons per square inch without failing. Such

steels are made into tubes, rods, and wires. Another

type of steel that is used extensively is stainless steel.

This alloy resists corrosion and is particularly valuable

Figure 2-24.--Bending action occurring during carrier

for use in or near salt water.

landing.

2-20